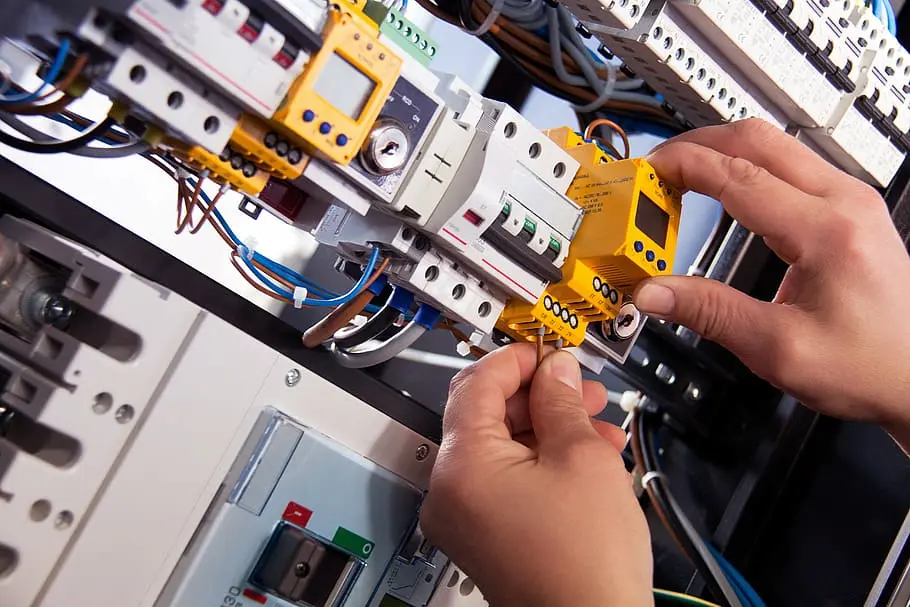

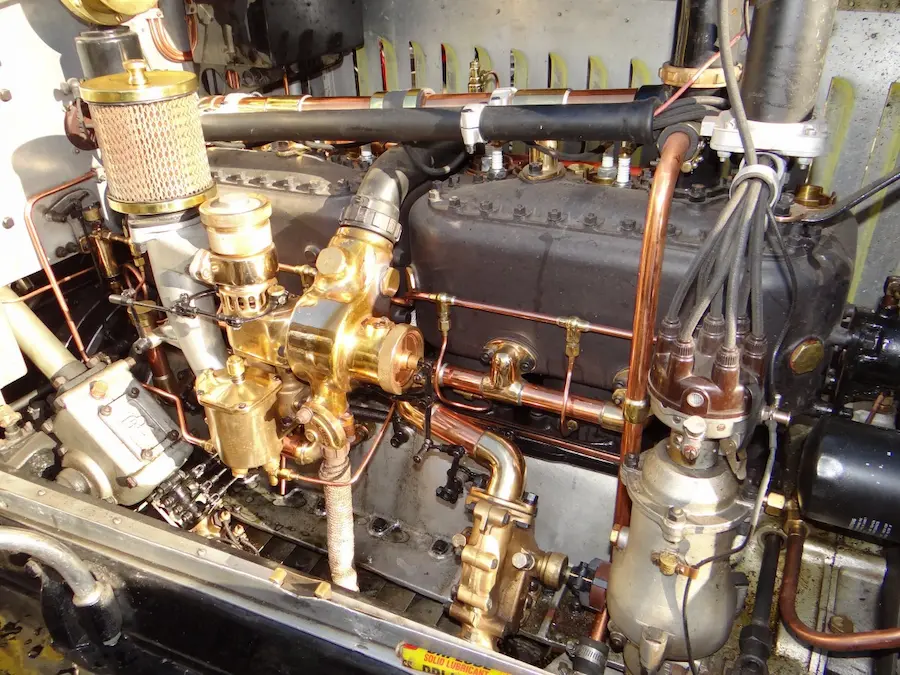

If you’ve ever looked in the history books at various factories and industrial complexes that involved heavy plumbing, especially around the period of the 19th and 20th centuries, then inevitably you’ve seen some industrial worker, helmet on, cigarette on the side of the mouth and sleeves cut off, working the control handle on a gate valve. Created with a simple but extremely effective screw design, gate valves are controlled and managed by literally turning a handle in a circle. That motion that either opens or closes the valve. One of the most common military applications of gate valves was in earlier submarines; just look at any war movie and more often than not, the actors are busy spinning away at gate valves to control the vessel.

An Old Technology That Still Works Fine Today

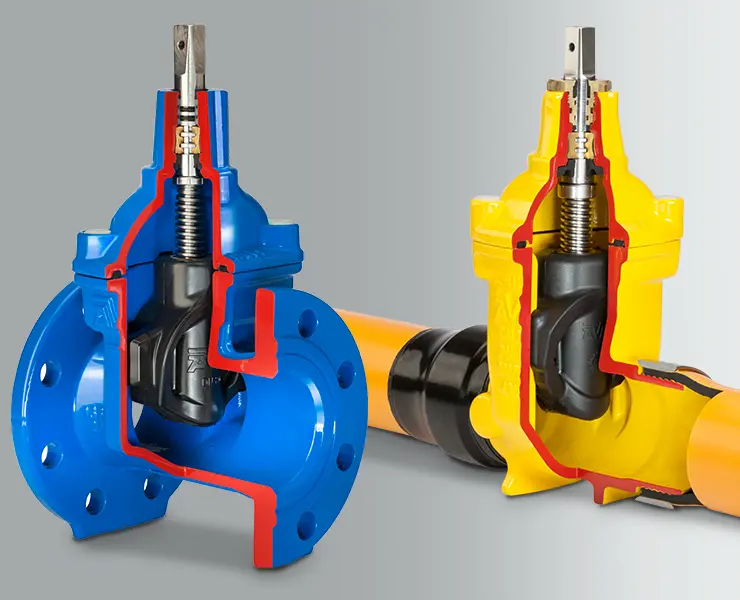

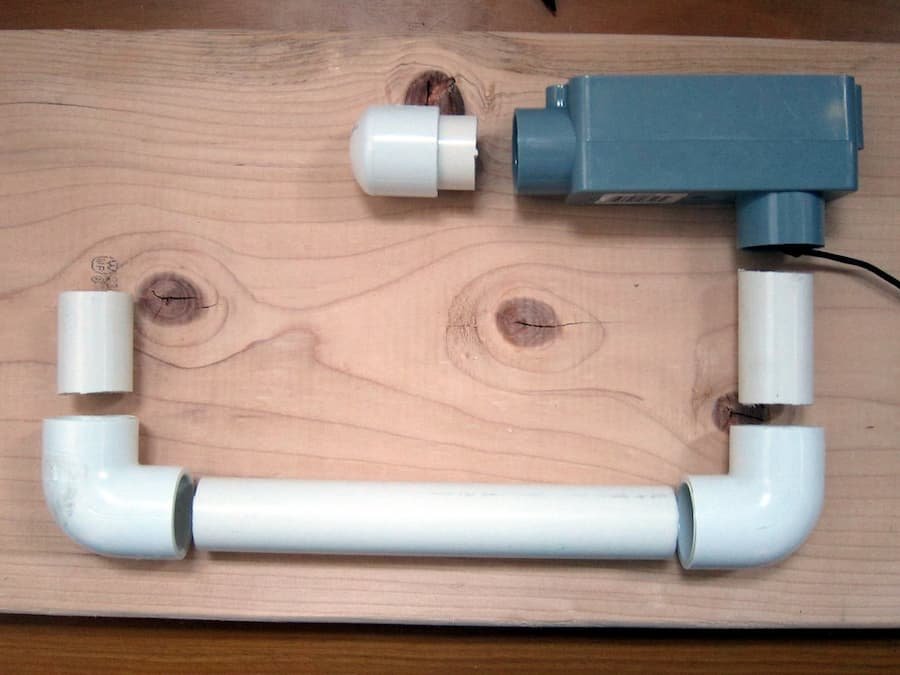

Eventually, gate valves had to move aside for better designs, including the plug valve as well as the ball version, and the butterfly. However, gate valves are still regularly used, particularly for valve systems managing large flow plumbing, such as oil, water, steam, and similar. The build on a gate valve still makes it extremely effective. Either the gate turns and rotates open or closed, or the screw nature pulls the gate block up or down as needed.

Some of the earliest documented gate valves go back as far as the mid to late 1840s, yet they are easily available and usable today on most plumbing systems. The simple nature of the turn dial control makes it one of the easiest analog plumbing controls to use and train people on, literally just requiring enough knowledge to know which way to turn when, and to have enough strength to make the valve turn as needed.

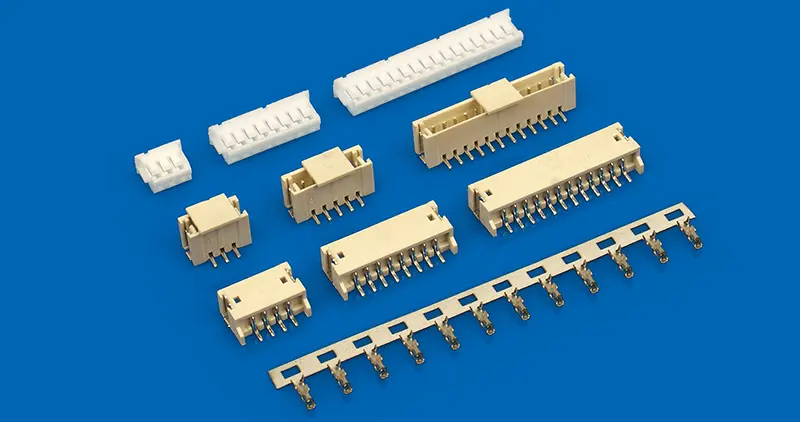

Finding Gate Valves on the Market

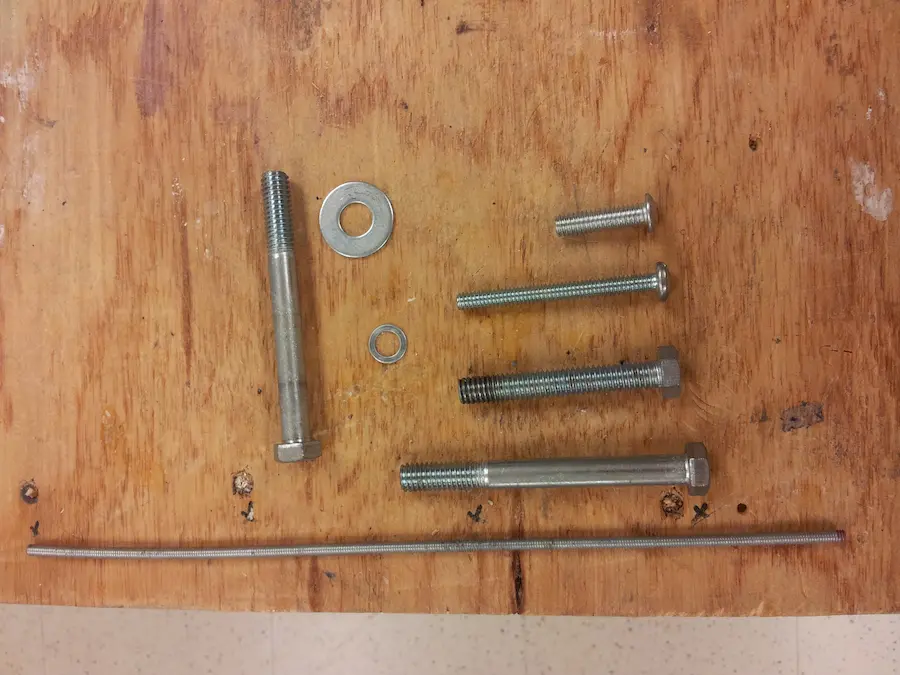

Gate valves are available from a gate valves distributor in a wide range of sizes and pressure tolerances, as well as thickness. A simple ½ inch valve can easily fit in one’s hand, and most folks have used them in water faucets without realizing it. The biggest valves are easily 144-inch models that give a truck a run for its money in size. Obviously, these monsters need a sizable control unit to turn them as well. They are fabricated with forging, casting, welds, and similar, mostly being one-unit systems with just the valve and control handle themselves being the add-on parts.

The beauty of the gate valve continues to be its simplicity. The design doesn’t get in the way of or impede the rate of flow when in an open position. However, it can fully shut off a flow confidently when moved to a closed position. There are no electronics involved. It’s purely an analog, mechanical function with a solid seal. Many refer to gate valves as block valves in the field. However, the weakness of the gate valve is that its application is all or nothing. They are a poor choice when flow through the line needs to be regulated or variable. More often than not, a partial opening creates too much pressure and wear, which ends up damaging the block inside the gate valve.

Again, gate valves are extremely popular and applicable in many industrial settings, which is why they continue to be used despite more advanced technology being available. It also doesn’t hurt that the cost of a gate valve for the same function is considerably less too, keeping savings in a facility’s pocket for higher priorities.

0