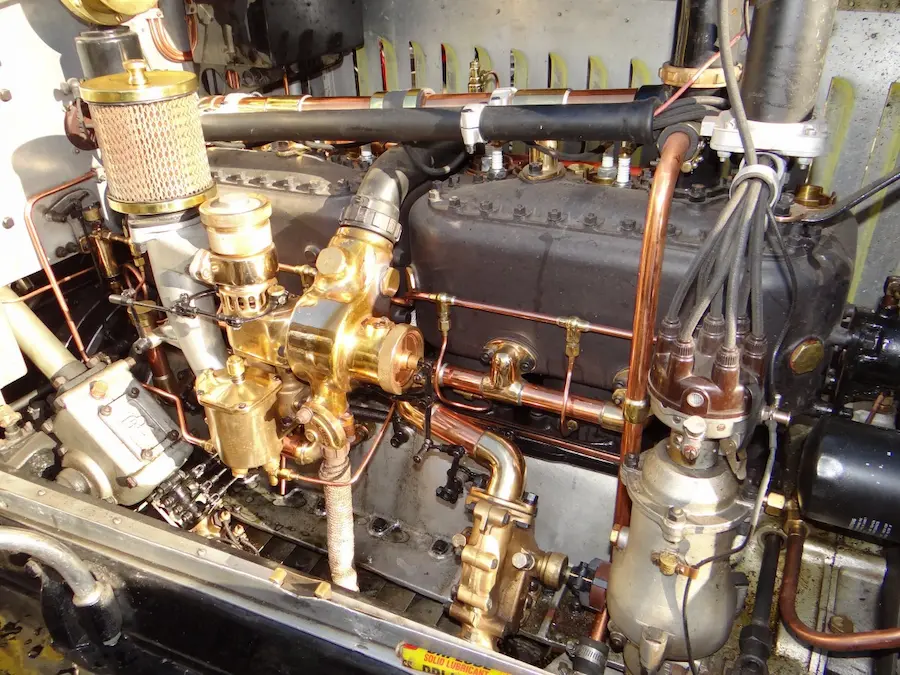

CNC machinery has been growing in popularity for some time. Using CNC machines improves accuracy, increases productivity, reduces waste, and decreases the possibility of human error. How do these machines accomplish this?

CNC stands for computer numerical control machines. An operator inputs the job specifications to the computer, and the computer determines where and how much to cut, how the object should be placed, and any other necessary components.

Table of Contents

Basic CNC Machines

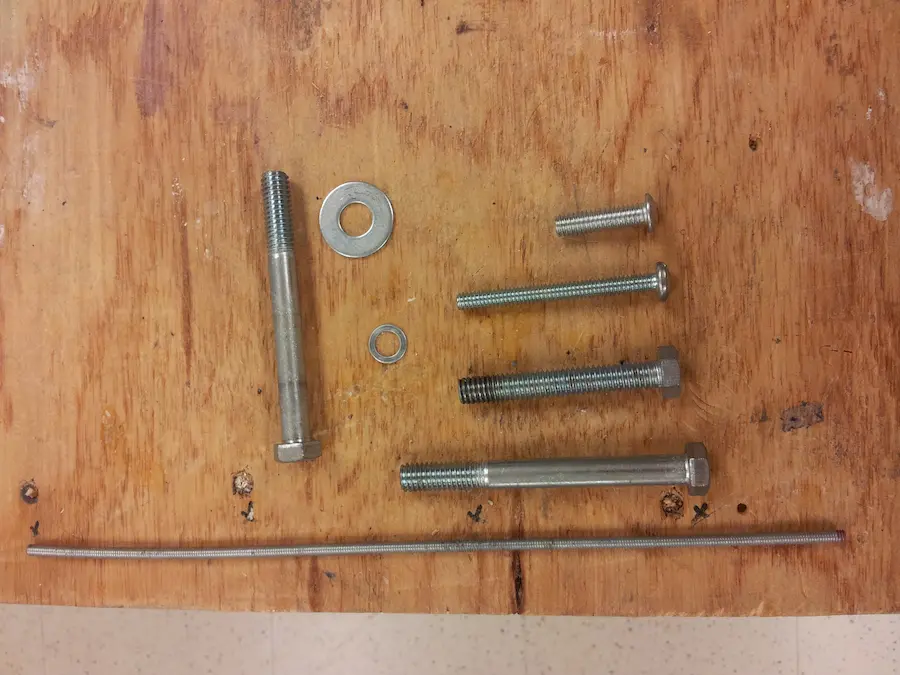

A CNC machine company typically has several types of machines it uses, depending on the job at hand. The following are the basic machines used:

CNC Lathe Machines

These machines have a lathe, which is used to move the object being cut. Once the specifications are inputted into the CNC machine, the lathe moves the object into the necessary position to ensure the tools are able to cut it properly.

CNC EDM Machines

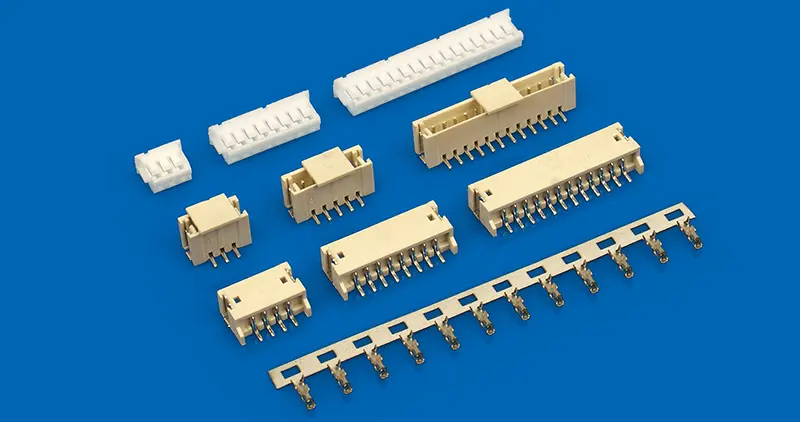

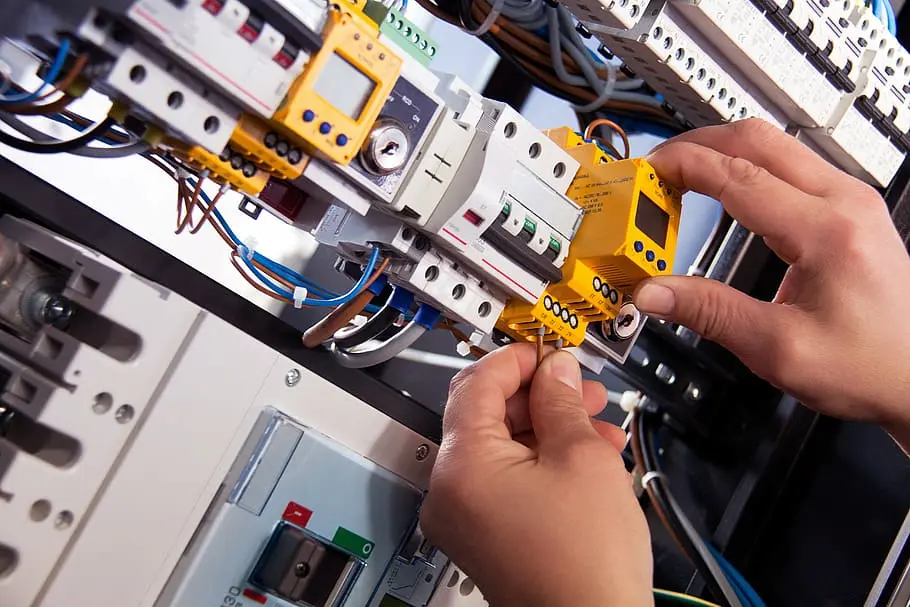

EDM or electric discharge machines utilize the corrosive power of electric sparks to cut away excess material. In order to do this effectively, the material that is to be cut is placed between two electrodes. The CNC machine and operator determine how much electrical discharge the job requires, and ensure the correct amount is produced by the electrodes.

CNC Milling Machines

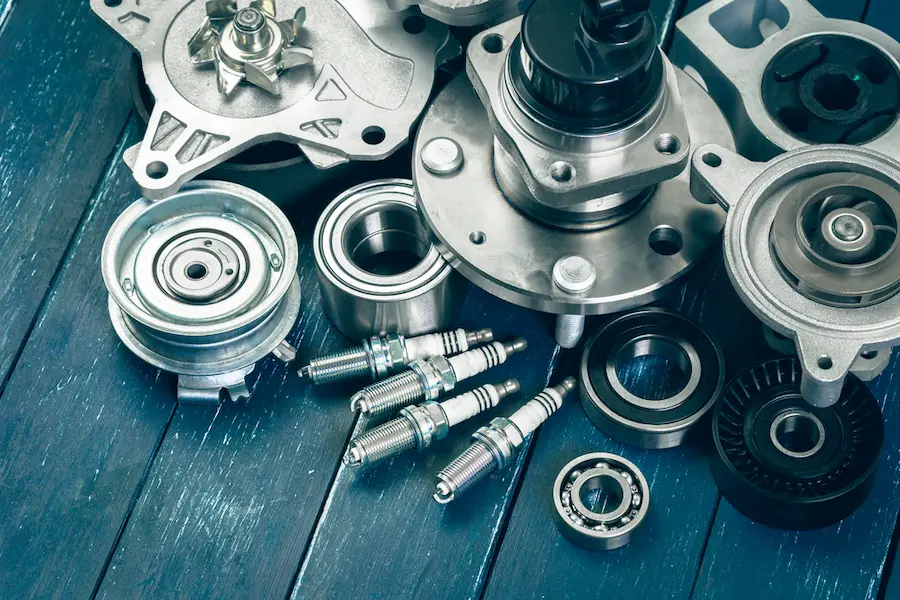

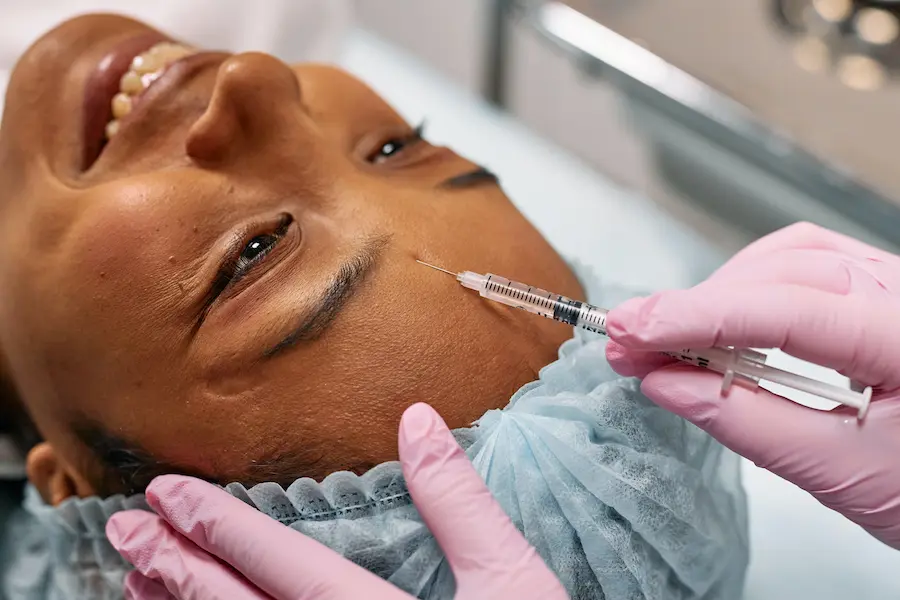

A milling machine is one of the most common types of CNC machines. Through milling, tools rotate along up to six axes to precisely cut the material away. A CNC machine company typically uses milling to cut parts for automobiles, shipping, oil drilling, aerospace, and medical industries.

CNC Laser Cutting Machines

CNC laser cutting machines use lasers to cut through tough material. Typically, they either use a CO2, neodymium, or Nd: YAG laser. These lasers offer a great deal of accuracy and precision.

CNC Plasma Cutting Machines

CNC plasma cutting machines are somewhat similar to laser cutting machines. The difference is that, instead of lasers, plasma cutting machines use a plasma torch to do the cutting. This option has greater strength than laser cutting machines, but lasers provide more precision. A CNC machine company determines the best tool, depending on the specifications of each job.

CNC machinery companies can help produce more uniform products with greater accuracy and lower costs. If machining services make up part of your manufacturing process, consider utilizing a company that specializes in CNC over traditional methods.

Additionally, if you are considering a new career path, becoming a CNC operator can be a good choice. The use of CNC is not a trend. It’s an efficient method of machinery that will continue to grow, offering a good job outlook in the future.

Read also: Profit Updates For ASL Sign Sales & Service

0