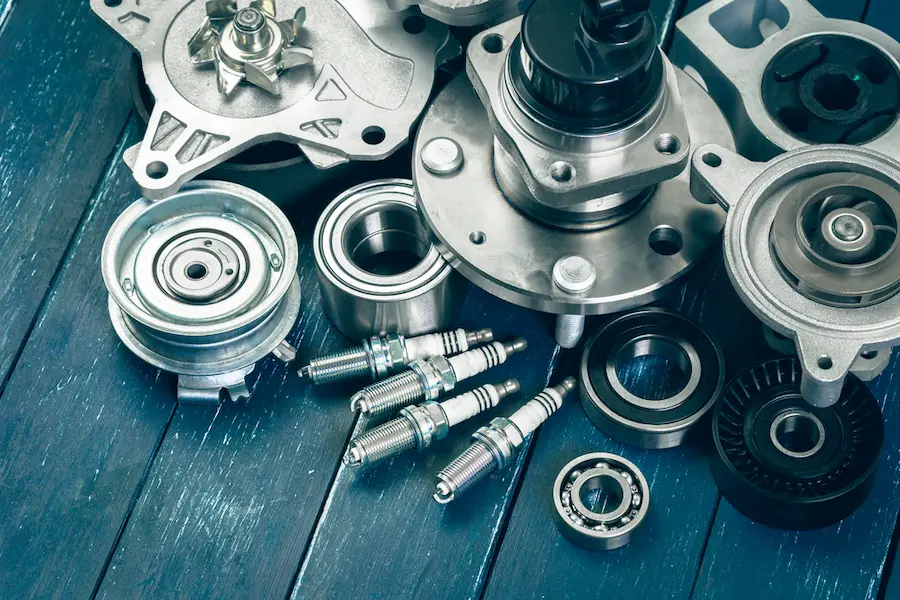

Aerospace anodizing is a process that adds a metallic finish to aluminum. The finished product has a rich, dark luster and a mirror-like finish. It is the standard finish for aircraft, space vehicles, and industrial equipment. The process is also known as electro-deposit-coating or EDC. Aerospace anodizing is not just for aircraft; it is also used on a multitude of different products, including sports equipment, furniture, and tools.

Table of Contents

Types of Aerospace Anodizing

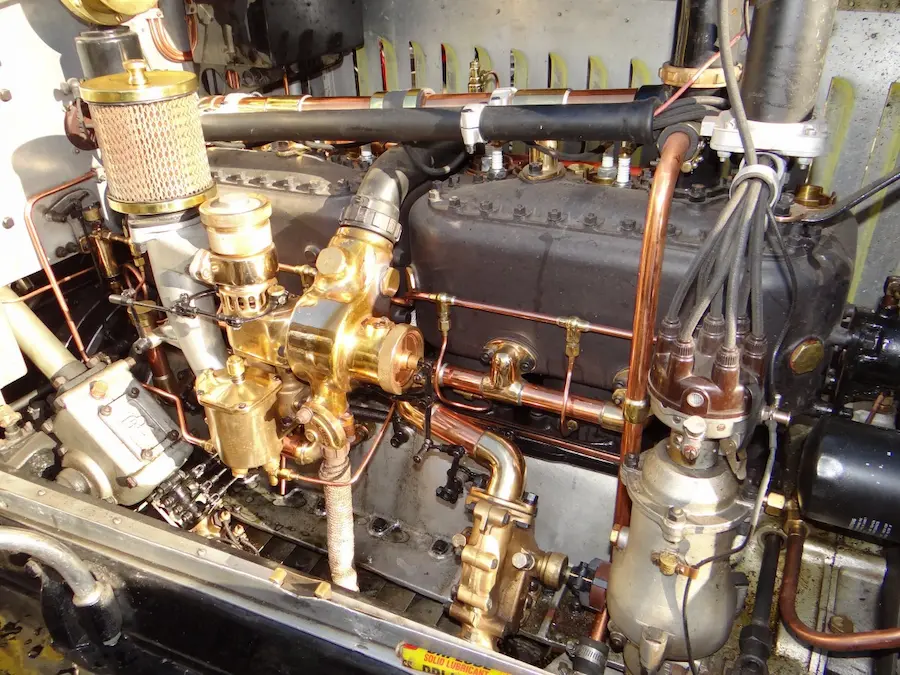

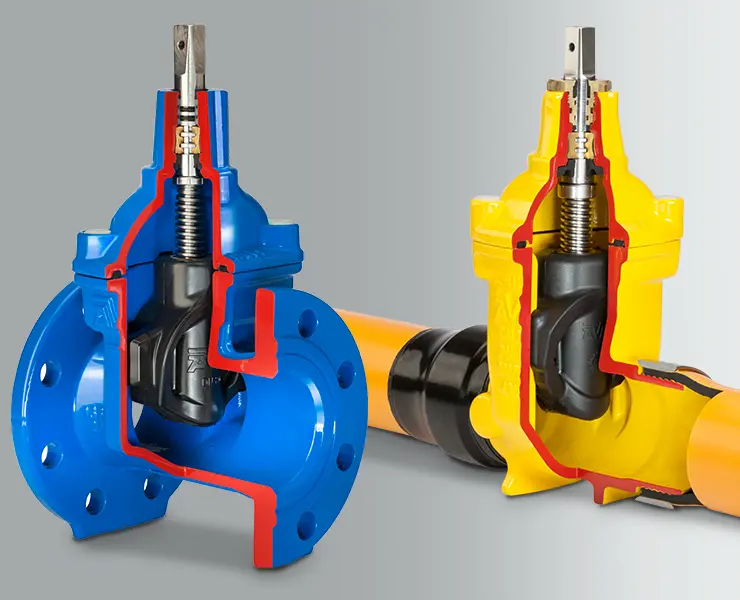

– Hot Dip Galv – This is the most common type of aerospace anodizing. It is done by dipping the material into a vat of anodizing solution and then submerging the item into a tank of anodizing electrolyte. In this process, the aluminum object is submerged in a bath of anodizing electrolyte, which is an aqueous sulfuric acid/sodium sulfate solution. The acid reacts with the aluminum and deposits a thin, nickel-rich coating that turns dark over time.

– Cold Dip Galv – In cold dip anodizing, a coating solution is applied to the aluminum object and then frozen. This process speeds the process of anodizing and reduces the number of coatings needed. However, the cold dip process can yield inconsistent results, especially for high-quality parts.

– Powder Coating – Powder coating is similar to hot dip but without the immersion step. Instead, a powder-coated object is held in a pressurized air environment where the coating is applied. Powder coating is often used on components that do not require an extremely durable finish or are not compatible with immersion.

How Does Aerospace Anodizing Work?

Aircraft aluminum is susceptible to corrosion and degradation from the elements. A metallic finish can help prevent corrosion and extend the lifespan of the part. Aerospace anodizing is a process that deposits a thin, nickel-rich coating on aluminum. The process works by dipping the part in anodizing solutions and then exposing it to an electrolyte solution. The nickel coating reacts with the aluminum, and the parts are bathed in a dark luster. The process is similar to the way a silver watch is made. Both silver and anodizing work by exposing the silver to an electrolyte and then plating the silver with nickel. However, silver is more reactive and can be plated multiple times while nickel is more stable and only gets plated once.

Tips for Successful Aerospace Anodizing

– Use the Correct Anodizing Solutions

– The aerospace industry has strict standards for the anodizing solutions used in the process. Choosing a standard that does not meet the specifications can lead to inconsistent results, especially for high-quality parts. There are many different aerospace solutions, so it is important to understand the difference between them and pick one that best suits the part you are coating.

– Clean the Part – Aerospace parts are often coated with a layer of grease or oil. Contamination will prevent the parts from reaching their full potential. Even parts that are clean can have issues if they are not thoroughly cleaned.

– Use a Good Quality Parts Washer – Aerospace parts are exposed to harsh environments, which can lead to corrosion and thickness issues. A parts washer is an essential tool during anodizing.

– Follow the TimeTable – It is important to follow the timetable provided when coating parts. Incorrect times can lead to inconsistent results and damaged parts.

– Use a Protective Muffler – Aerospace parts are exposed to harsh environments, which can lead to corrosion and thickness issues. A parts washer is an essential tool during anodizing. Protective mufflers are another useful tool that can help protect the part.

0