Coiled Tubing Winch technology has restructured the oil and gas industry by allowing the extraction of oil and gas from deep underground reservoirs in a safer and more well-organized manner. Technology has come a long way since its start, and new developments have made it even more reliable and secure for the workers involved.

If you’re looking to improve safety in your oil and gas operation, here are some ways that Coiled Tubing Winch technology can help:

Table of Contents

How Does Coiled Tubing Winch Technology Help?

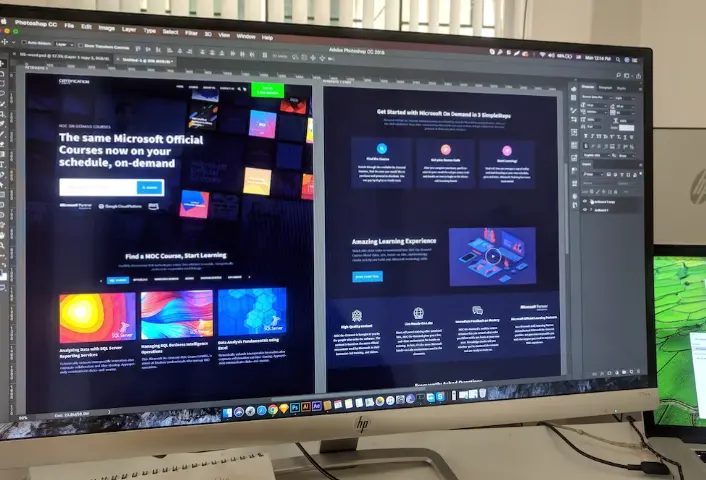

1. Automated Winch Control Systems

Automated control systems are a significant advancement in Coiled Tubing Winch technology. They reduce the need for manual input, preventing accidents caused by human error. These systems can also automatically shut down the winch in an emergency, improving safety.

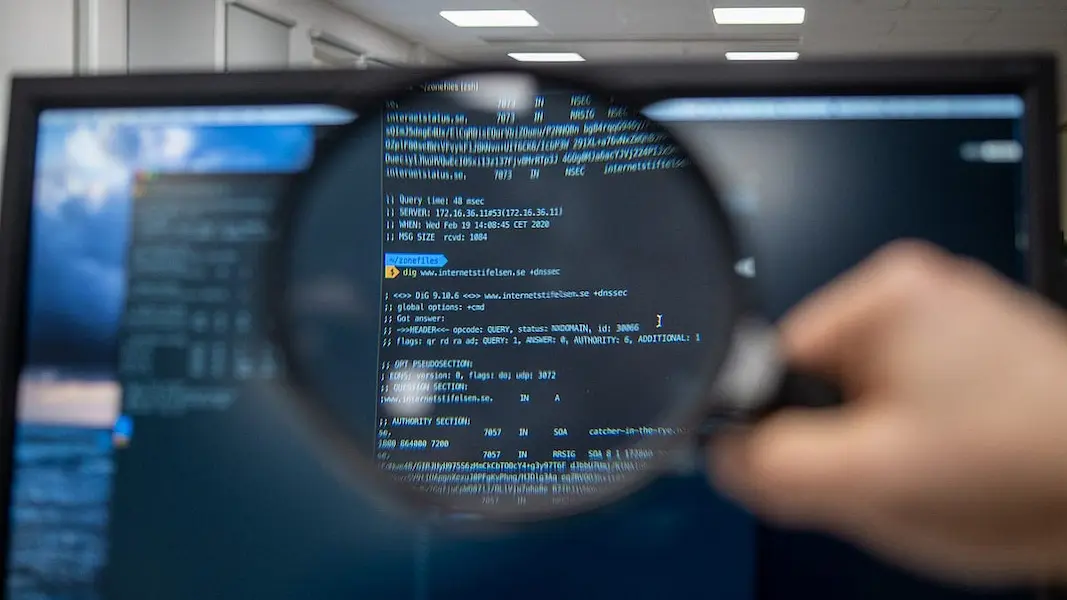

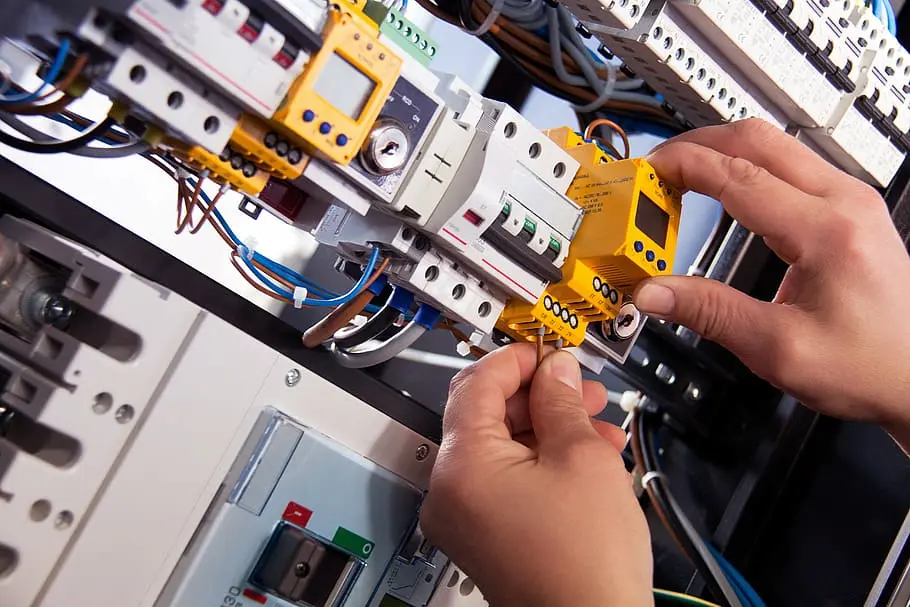

2. Real-Time Monitoring Systems

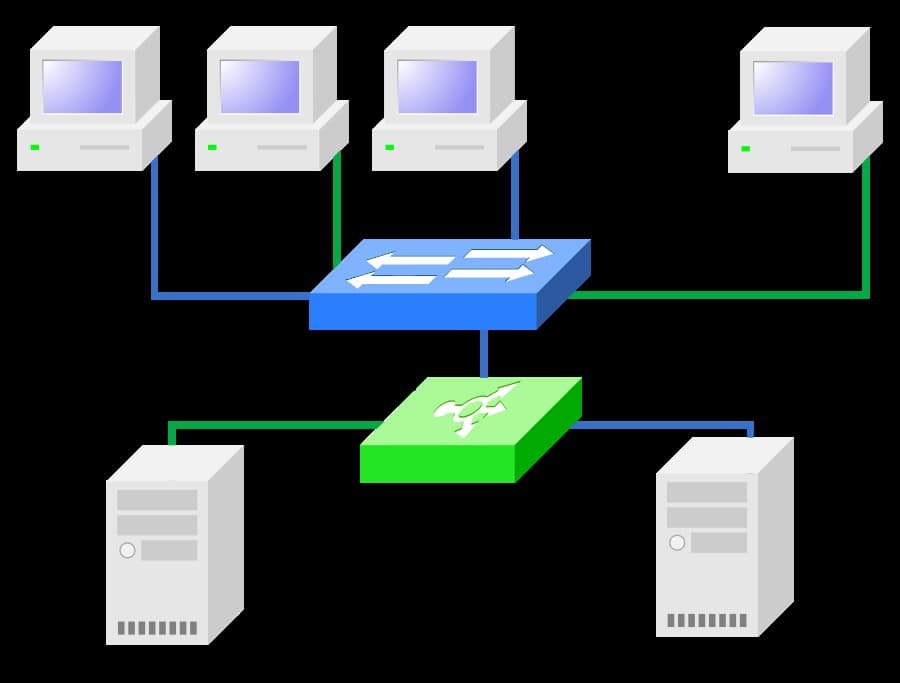

Coiled Tubing Winch technology can also be equipped with real-time monitoring systems that allow for better control and regulation of the winch operations. These systems can monitor various frameworks such as load, tension, speed, and torque. With this data, operators can make better decisions and adjustments to ensure the winch operates safely and efficiently.

3. Better Training for Operators

Another way to boost safety with Coiled Tubing Winch technology is to provide better training for operators. Operators need to be familiar with the winch equipment and its operating procedures. This includes understanding the various controls and indicators, as well as the correct use of safety equipment such as personal protective gear.

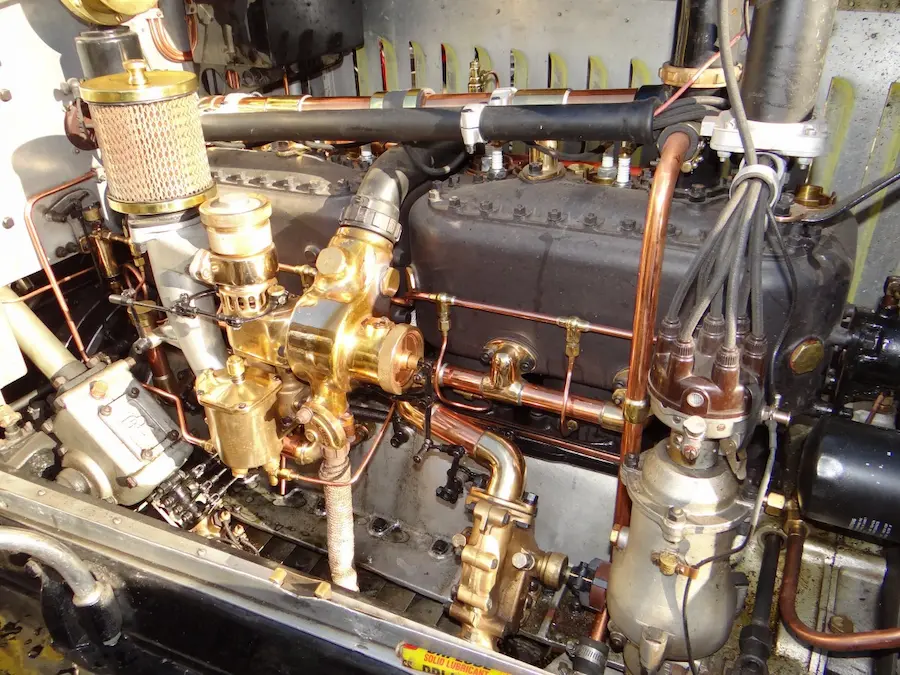

4. Regular Maintenance and Inspection

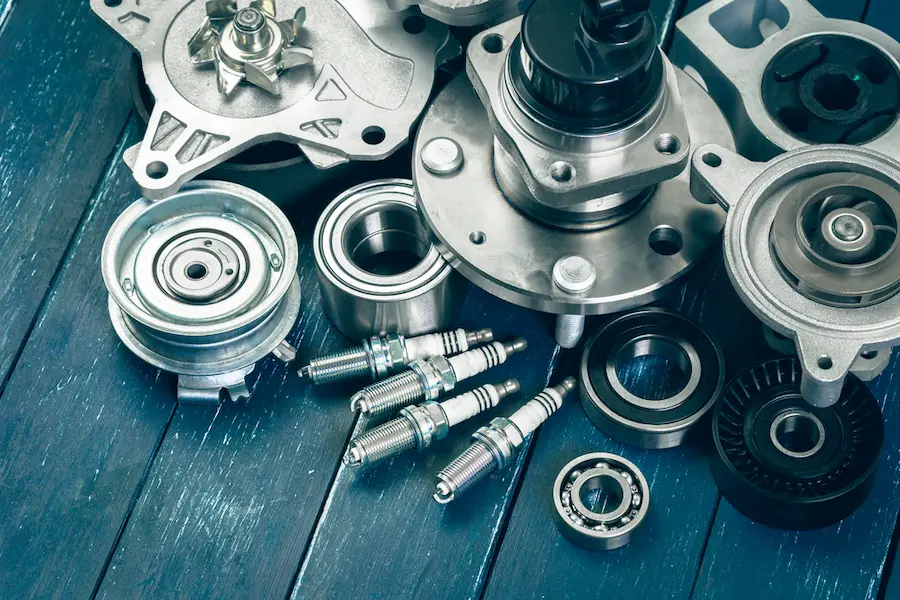

It would help if you inspected the coiled tubing winch equipment regularly to ensure it functions correctly. This includes checking for wear and tear on various components, lubricating moving parts, and checking for any signs of damage. Regular maintenance and inspection can help to prevent accidents caused by equipment failure.

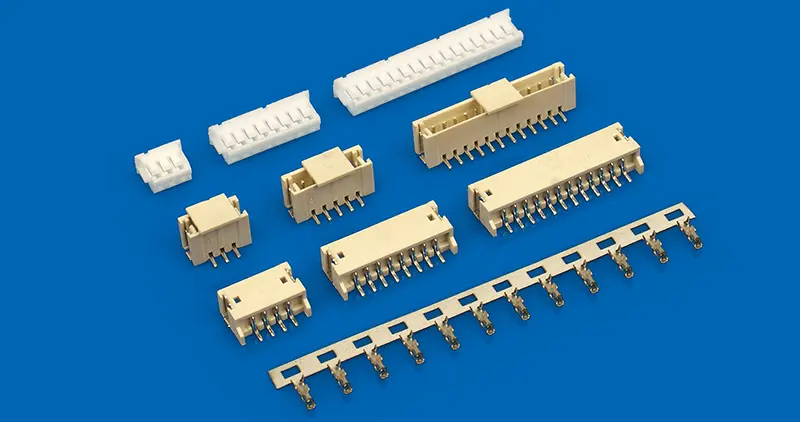

5. Use of Safety Devices

Coiled Tubing Winch equipment can also be equipped with various safety devices such as limit switches, emergency stop buttons, and safety interlocks. These devices are designed to prevent accidents by shutting down the winch in emergencies, such as overloading or over-speeding the winch. Additionally, you can program these to trigger alarms or alerts in case of abnormal operating conditions, allowing for quick intervention by the operator.

How to choose the right Coiled Tubing Winch?

1. Capacity:

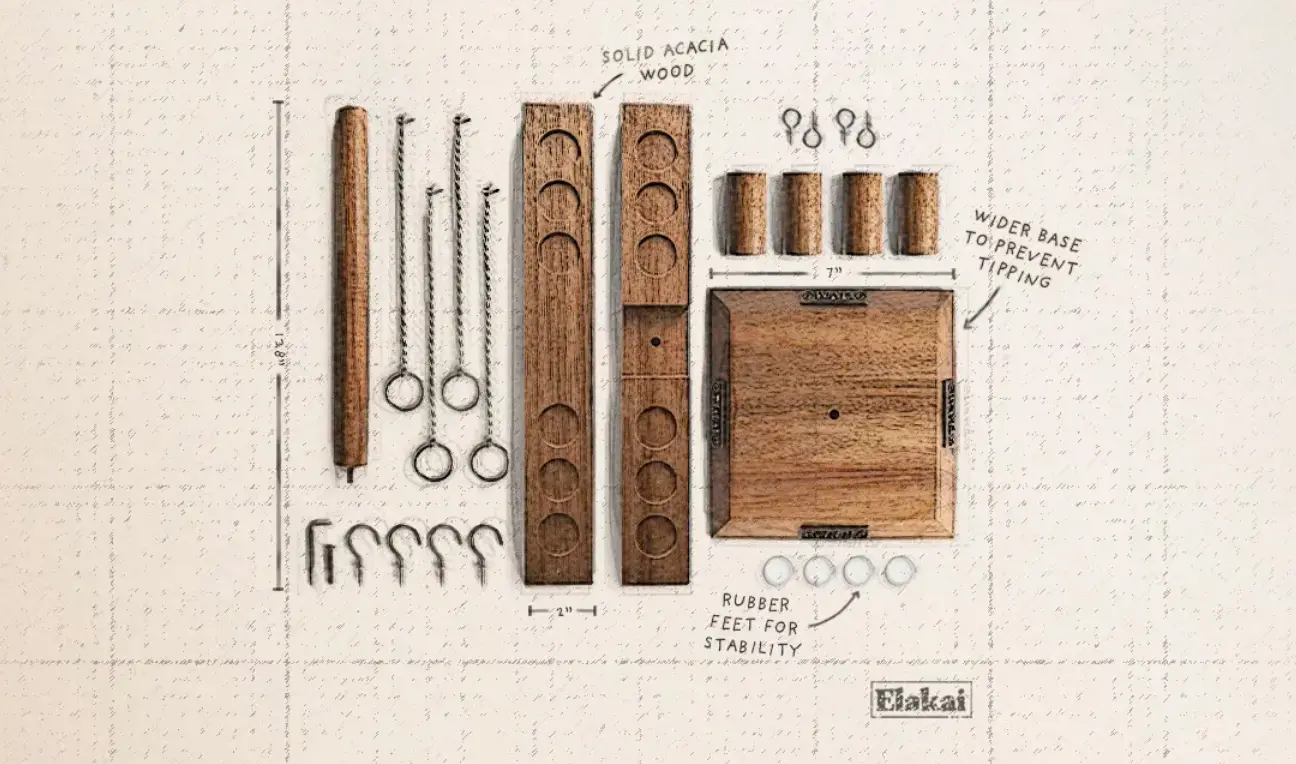

The capacity of a coiled tubing winch refers to the amount of weight it can handle. You will want to choose a winch with a power that matches the importance of the coiled tubing you will use. If you plan to use heavier coiled tubing in the future, you may want to consider a winch with a higher capacity. Reel Power ME Coiled Tubing Winch-Designed for up to 80,000 lbs of CT tension (120,000 lbs available).

2. Size:

The size of the winch is also important. You will want to choose a winch that is the right size for your vessel or rig and can accommodate the length and diameter of the coiled tubing you will be using. A winch that is too small may not be able to handle the weight of the tubing, while a winch that is too large may be cumbersome and difficult to manoeuvre. Reel Power ME Coiled Tubing winch-Designed for 2” Coiled Tubing – Catahead chains can be replaced on-board to handle other CT sizes (2 3/8” size available).

3. Power:

The winch’s power refers to its ability to handle coiled tubing efficiently. You’ll want to choose a winch with enough force to handle the job without straining the equipment or the tubing. Factors that can hit power include the tubing’s size and weight and the wellbore’s depth and angle.

4. Control system:

The control system of the winch is also an important consideration. You will want to choose a winch with a control system that is easy to use and allows for precise control of the coiled tubing. Some winches come with remote control systems that allow for operation from a safe distance.

5. Safety features:

Finally, you will want to choose a coiled tubing winch with safety features to protect workers and equipment. Some standard safety features include emergency stop buttons, load monitoring systems, and automatic shut-off systems. Reelpower OG’s Patented Failsafe Parking & Emergency Brake are included.

Bottom Line

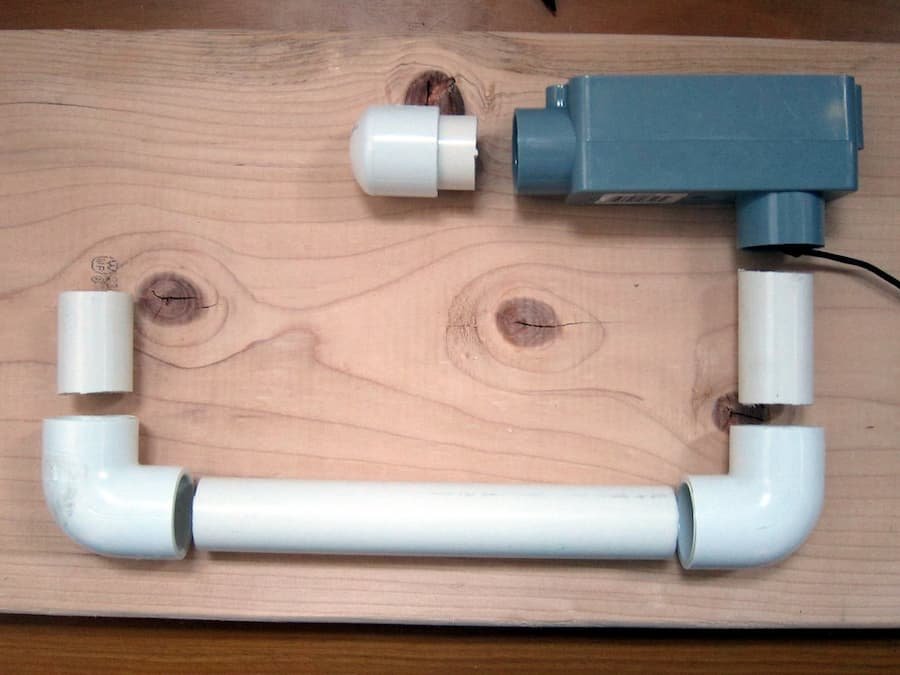

Most coiled tubing winches use a heavy device to handle and store tubing. This tubing is then deployed to a tower sheave and injected into the well. But the Reel Power ME patented unit has a unique curved injector that handles the load. This design is smaller and can be placed near the moonpool or over the railing. It doesn’t require a tower sheave and saves space. The tubing is wound onto the reel with normal tension.

0