In today’s competitive business landscape, personalisation and attention to detail can make all the difference. Whether in the trophy-making business, crafting personalised gifts, or being involved in industrial manufacturing, investing in the right engraving machine is crucial for achieving precision and excellence in your work. With many options available, selecting the best engraving machine for your business needs can be daunting. This guide will walk you through the key factors to consider, helping you make an informed decision that aligns with your business requirements.

Table of Contents

Understanding Your Business Needs

Before delving into the technical specifications of engraving machines, it’s essential to have a clear understanding of your business needs. Consider the type of materials you’ll be working with, the work volume, and the required level of detail. Are you primarily engraving metals, plastics, or wood? Will you be handling intricate designs or large batches of products? These questions will serve as a foundation for determining your ideal engraving machine’s features.

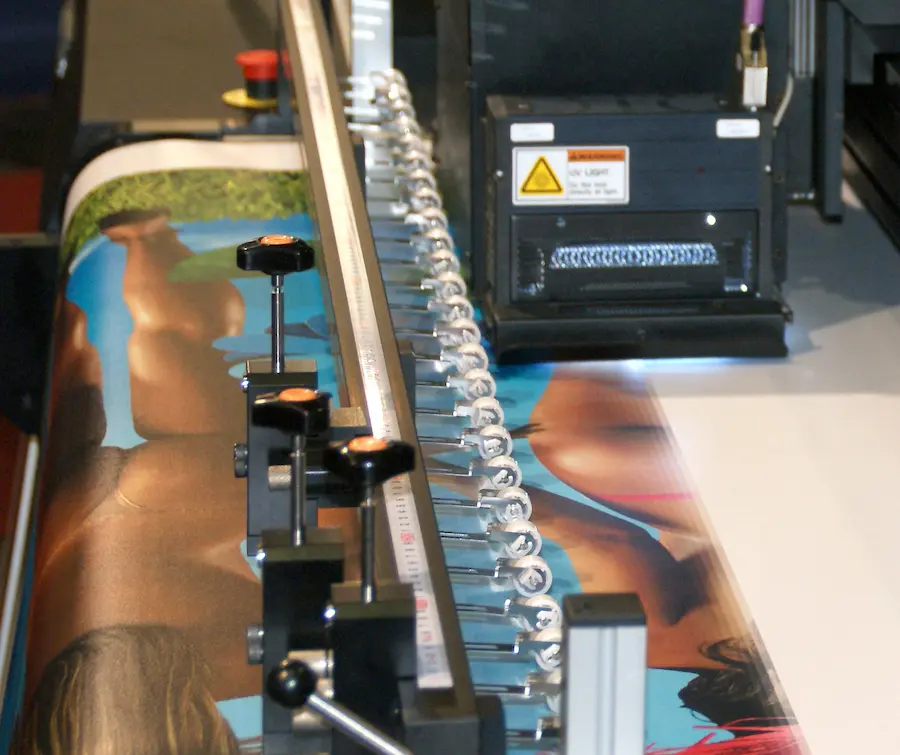

Engraving Techniques: Rotary vs. Laser

Engraving machines generally fall into two categories: rotary and laser. Each has its unique advantages and is suited to different applications.

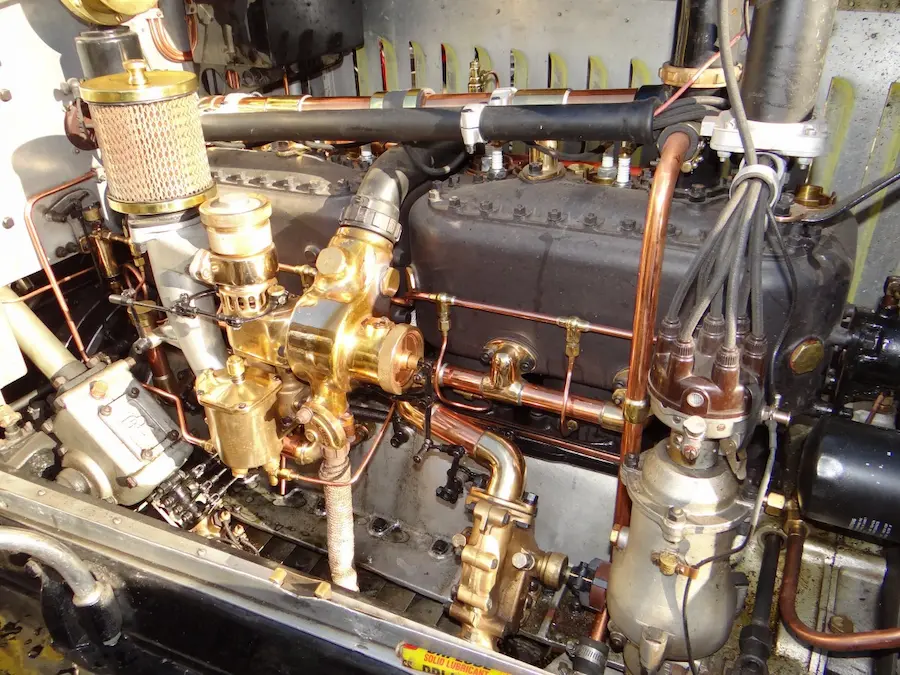

Rotary Engraving Machines:

- It is ideal for traditional engraving on metal, glass, wood, and other materials.

- Utilizes a rotating cutting tool to create detailed designs and text.

- Well-suited for producing tactile, deep engravings.

Laser Engraving Machines:

- Versatile, capable of engraving on various materials, including wood, acrylic, leather, and some metals.

- It uses a laser beam to vaporize or remove material, allowing for precise and intricate designs.

- Well-suited for high-speed and large-scale production.

Consider the nature of your business and the materials you will be working with to determine which engraving technique aligns better with your requirements, such as a portable handheld laser engraver.

Speed & Efficiency

The efficiency of your business operations is closely tied to the speed of your engraving machine. High-speed machines are essential for meeting tight deadlines and handling large volumes of work. However, it’s crucial to strike a balance between speed and precision. A machine that sacrifices accuracy for speed may not be suitable for intricate designs or detailed engraving work. Evaluate the production speed of the machines you’re considering and ensure they align with the demands of your business.

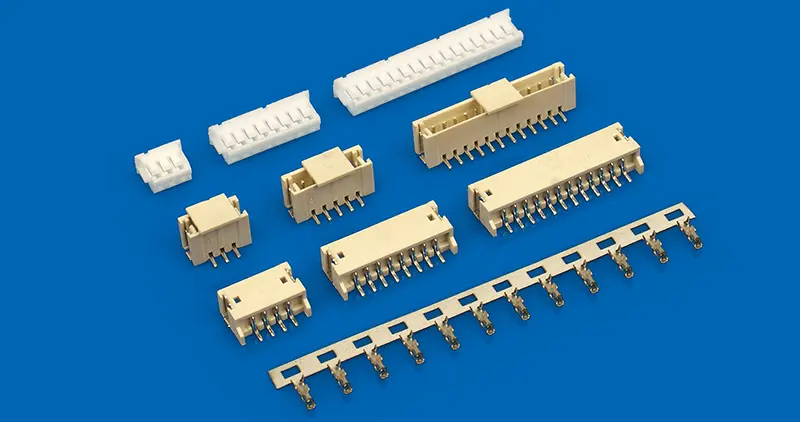

Material Compatibility

Different engraving machines are designed to work with specific materials. Before purchasing, ensure that the machine you’re considering is compatible with the materials you commonly use in your business. Whether metal, plastic, wood or a combination of materials, the engraving machine should deliver consistent, high-quality results. Additionally, consider the maximum size of the materials the machine can accommodate to ensure it meets the scale of your projects.

Software & Compatibility

The software accompanying an engraving machine is a critical factor in its functionality. A user-friendly and feature-rich software package can significantly enhance the capabilities of your machine. Look for engraving machines compatible with popular design software or their proprietary software, which offers a range of design tools and customisation options. The ability to import and export various file formats should also be considered, ensuring seamless integration into your existing workflow.

Precision & Resolution

The level of precision and resolution an engraving machine offers is paramount, especially if your business involves intricate designs or small text engraving. Check the machine’s specifications for details on its resolution capabilities. Higher-resolution machines can produce finer details and sharper edges, producing a more professional and polished final product. Consider the level of detail your business demands and choose a machine to meet those requirements.

Maintenance & Durability

An engraving machine is an investment in your business, and its durability and ease of maintenance are crucial factors to consider. Look for machines with sturdy construction and high-quality components that can withstand the demands of regular use. Additionally, inquire about the maintenance requirements of the machine, including routine cleaning, lubrication, and any potential issues that may arise. A machine with minimal downtime and straightforward maintenance procedures will contribute to the overall efficiency of your operations.

Cost & Return On Investment

While the initial cost of an engraving machine is a significant consideration, viewing it in the context of the long-term benefits it can bring to your business is essential. Consider the return on investment (ROI) the machine will provide over time. You may justify a higher upfront cost if the machine offers advanced features, superior precision, and increased efficiency, leading to higher productivity and customer satisfaction.

Selecting the best engraving machine for your business involves carefully considering various factors, from the type of engraving technique to the machine’s speed, precision, and software compatibility. By understanding your business needs and evaluating machines based on these criteria, you can make an informed decision that aligns with your production requirements and long-term goals. Investing in the right engraving machine is not just a purchase; it’s a strategic decision that can elevate the quality of your work, enhance efficiency, and contribute to the success of your business in the competitive market.

0