Table of Contents

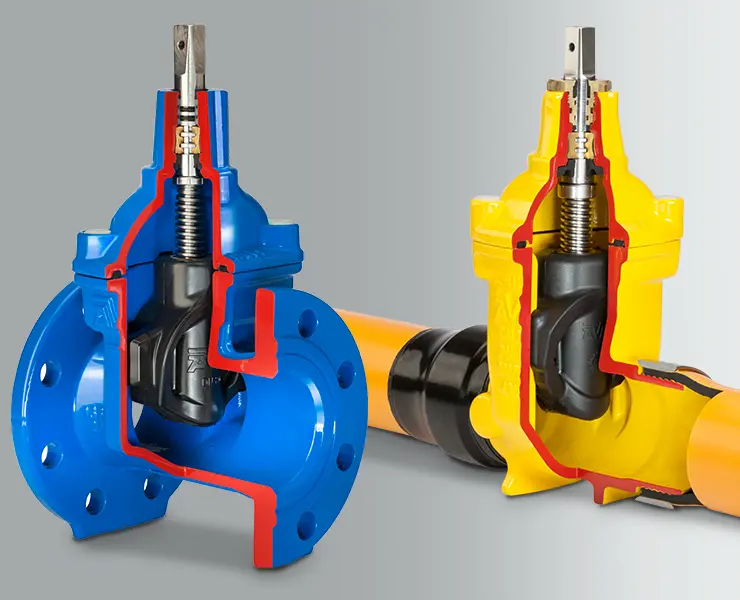

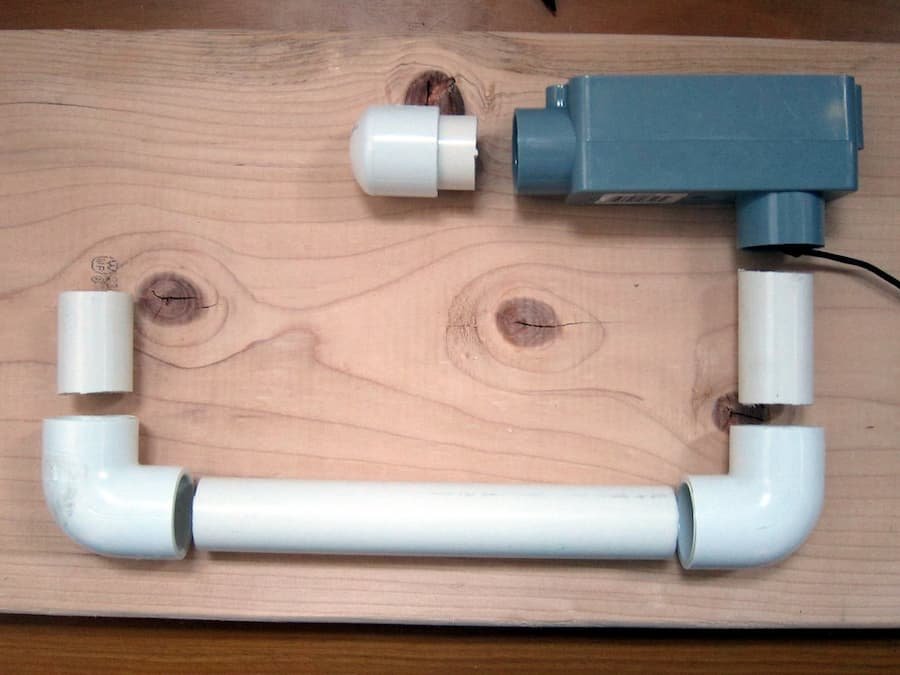

Introduction to Pipeline Pigs

Pipeline pigs are essential tools in the oil and gas industry and are crucial in maintaining pipeline efficacy. Ranging from simple cleaning devices to advanced inspection instruments, these tools, such as various pigging types, help ensure smooth and safe transport of fluids. Their usage helps prevent costly disruptions and maintains the integrity of pipeline systems

The term “pig” might sound peculiar, but it stands for “Pipeline Inspection Gauge” and has become synonymous with the various mechanical devices used in pipeline operations. Their versatility and functionality have made them indispensable in the industry. Over the years, pigs have evolved from essential cleaning tools to sophisticated devices loaded with sensors and data analysis capabilities.

Types of Pipeline Pigs

Pipeline pigs come in multiple types, each serving specific purposes. The three primary categories are:

Utility Pigs

Utility pigs are predominantly used for cleaning and maintenance. They remove build-up and other debris that may affect the pipeline’s efficiency. Common utility pigs include brush pigs, scraper pigs, and foam pigs. Brush pigs use bristles to scrape off deposits from the pipeline walls, while scraper pigs utilize blades to clear larger debris. Foam pigs are flexible and can navigate through pipelines with various diameters, making them highly versatile for different cleaning needs.

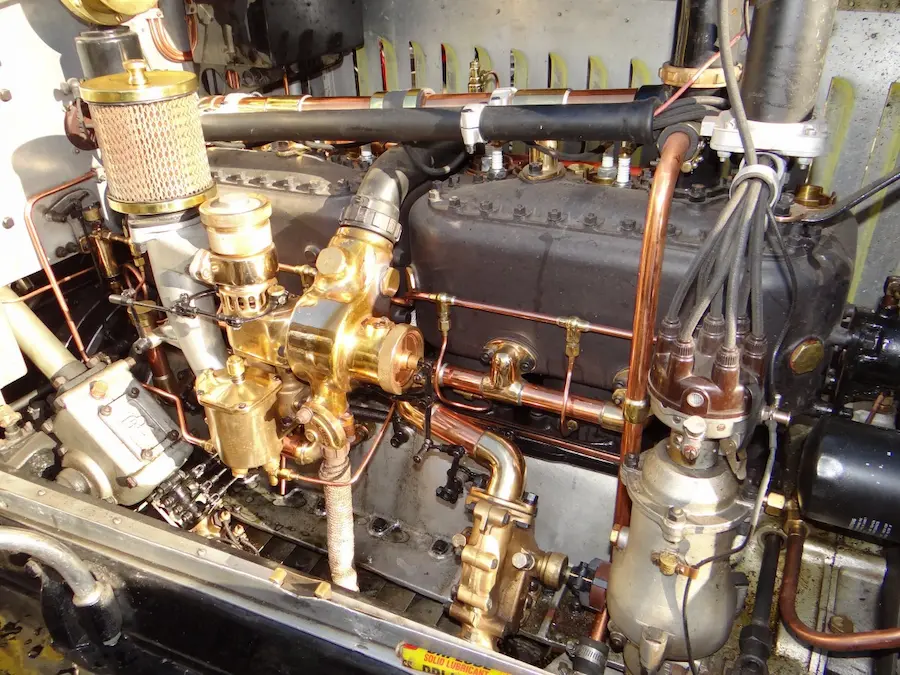

In-Line Inspection Pigs

In-line inspection pigs are sophisticated devices equipped with sensors and recording tools. They identify pipeline defects such as corrosion, cracks, and other anomalies that could lead to significant issues if left unaddressed. Inspection pigs often use magnetic flux leakage (MFL) technology or ultrasonic sensors to detect and measure the severity of defects, providing critical data for preventive maintenance actions.

Gel Pigs

Gel pigs are used primarily for liquid batching and dewatering. These pigs can adapt their shape to fit the pipeline, making them very effective for removing leftover liquids. Their gel-like consistency ensures they can push through residual fluids and contaminants, leaving the pipeline dry and clean for subsequent use. Gel pigs also effectively seal and isolate pipeline sections during maintenance operations.

Applications and Benefits

Pipeline pigs are invaluable in various applications within the oil and gas sector. Key applications include:

- Cleaning: Regular cleaning of pipelines is essential for removing deposits, such as wax and other residues, that can accumulate over time, impeding flow and efficiency. Effective cleaning ensures that the pipeline operates at optimal capacity, reducing the risk of blockages and flow restrictions.

- Inspection: Inspection pigs detect internal and external deformities, providing crucial data for maintenance decisions. This data helps assess the pipeline’s condition and plan repairs before minor issues escalate into significant problems, thus enhancing the safety and reliability of the pipeline system.

- Separation: Some pigs are designed to separate different types of fluids, ensuring smooth transitions between phases of product transportation. This is particularly important in multiproduct pipelines transporting different fluids back-to-back, preventing contamination and ensuring product quality.

Beyond cleaning and inspection, the benefits of using pipeline pigs extend to improving operational efficiency and safety, which can significantly reduce maintenance costs and downtime. Utilizing pigs for routine maintenance not only prolongs the lifespan of pipelines but also enhances overall operational reliability, resulting in cost savings and fewer environmental risks.

Maintenance and Inspection

Proper maintenance and regular inspection of pipeline pigs are paramount. Key practices include:

Routine Cleaning

Ensuring the pigs themselves are clean prevents cross-contamination and maintains their effectiveness. After each use, pigs should be thoroughly cleaned to remove any residues picked up during the cleaning process. This ensures they are ready for the next operation without the risk of contaminating contaminants into the pipeline.

Regular Testing

Pigs, especially inspection pigs, should be tested regularly to confirm their sensors and operational components are functional. Regular calibration and testing of sensors ensure that the data collected during inspections is accurate and reliable, which is critical for making informed maintenance decisions.

Compliance Checks

Adherence to industry regulations is crucial for operational safety and efficiency. Regular audits and updates to pigging procedures are recommended. Compliance with standards ensures that pigging operations are performed safely and effectively, minimizing risks to personnel and the environment.

Technological Advances in Pipeline Pigs

Recent technological advancements have revolutionized the capabilities of pipeline pigs. These innovations include:

Smart Pigs

Intelligent pigs are embedded with advanced sensors and analytic tools that collect detailed data on pipeline conditions. These pigs can detect minute changes in the pipeline’s structure, such as wall thickness variations, corrosion, and cracks. The data collected is analyzed in real-time, allowing for immediate identification of potential issues and prompt corrective actions.

Automated Systems

Automation in pigging processes ensures more efficient and reliable pig operations, reducing manual intervention and associated risks. Automated pigging systems use computerized controls to manage the deployment and retrieval of pigs, optimizing the timing and frequency of pigging operations. This leads to more consistent maintenance practices and reduces the possibility of human error.

Common Challenges and Solutions

While pipeline pigs are highly effective, they do encounter challenges. Some common issues include:

Blockages

Blockages are a frequent problem, often mitigated using more advanced and specific cleaning solutions. Specialized pigs with enhanced scraping and brushing capabilities can clear the pipeline when blockages occur. In some cases, chemical cleaning agents may be used with pigs to dissolve stubborn deposits.

High Costs

The expenses associated with advanced pigging technology can be substantial. However, these costs are often offset by reductions in downtime and extended pipeline lifespans. Investing in high-quality pigs and regular maintenance can prevent costly repairs and replacements, making it a cost-effective strategy in the long run.

Technological Limitations

As pipelines evolve, keeping pace with technological developments in pigging devices is essential. Ongoing research and development are critical to overcoming these limitations. Collaborative efforts between industry experts and research institutions are driving innovations that enhance the capabilities of pipeline pigs, ensuring they remain practical tools as pipeline infrastructures become more complex.

Conclusion

Pipeline pigs are integral to efficient and safe oil and gas transport. Their multifunctionality and ongoing technological advancements underscore their indispensability in the industry. Staying updated with the latest developments and adhering to best maintenance practices ensures these tools operate at peak performance, offering long-term benefits and reliability. By leveraging the capabilities of pipeline pigs, industries can achieve better operational efficiency, safety, and cost-effectiveness, ensuring the sustainability of their pipeline infrastructures.

0