Table of Contents

Key Takeaways

- Discover the importance of regular pipeline maintenance.

- Explore the tools and techniques used in the maintenance industry.

- Learn about innovations that are shaping the future of pipeline care.

- Understand how proper maintenance can prevent costly damages.

Introduction

In the intricate world of pipeline infrastructure, efficient and effective maintenance is more than just a necessary evil—it’s a strategic advantage that enhances safety and longevity. As pipelines traverse varying terrains and climates, they are subjected to constant stress and potential environmental hazards. Therefore, understanding the comprehensive landscape of pigging types and other maintenance strategies is crucial. These strategies ensure that pipelines remain operational and efficient, ultimately reducing the risk of costly damage while prolonging the life of these critical transport systems.

What Makes Pipeline Maintenance Essential?

Maintaining pipelines is essential to preventing costly financial losses and environmental disasters. Regular maintenance ensures infrastructure reliability and identifies and addresses leaks before they become catastrophic. Proactive action and ongoing attention are required to safeguard natural ecosystems and promote sustainable development worldwide.

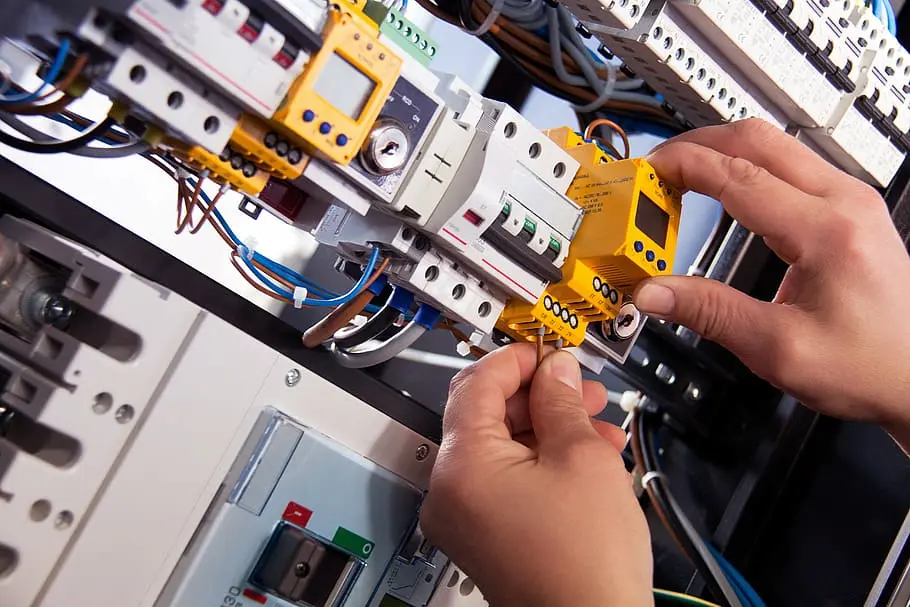

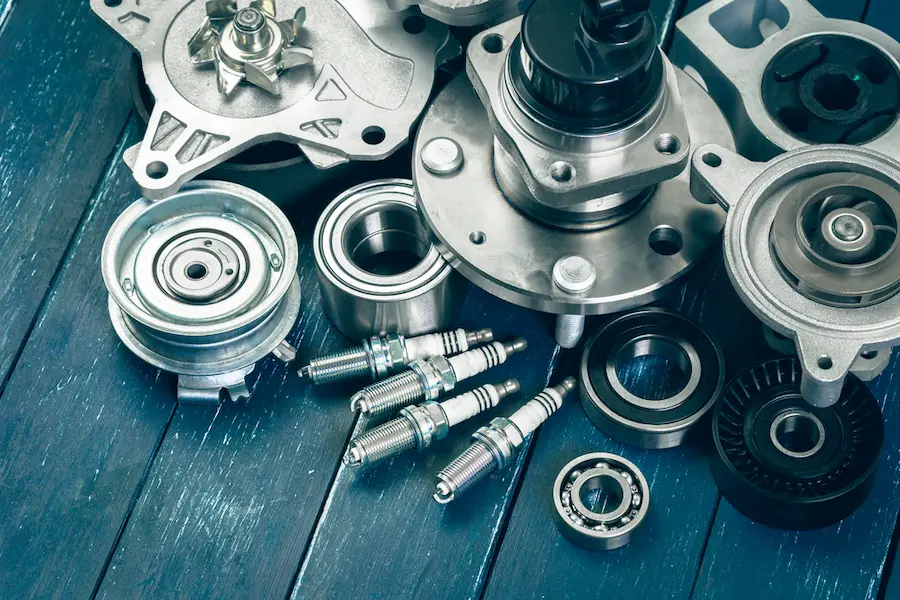

Tools of the Trade

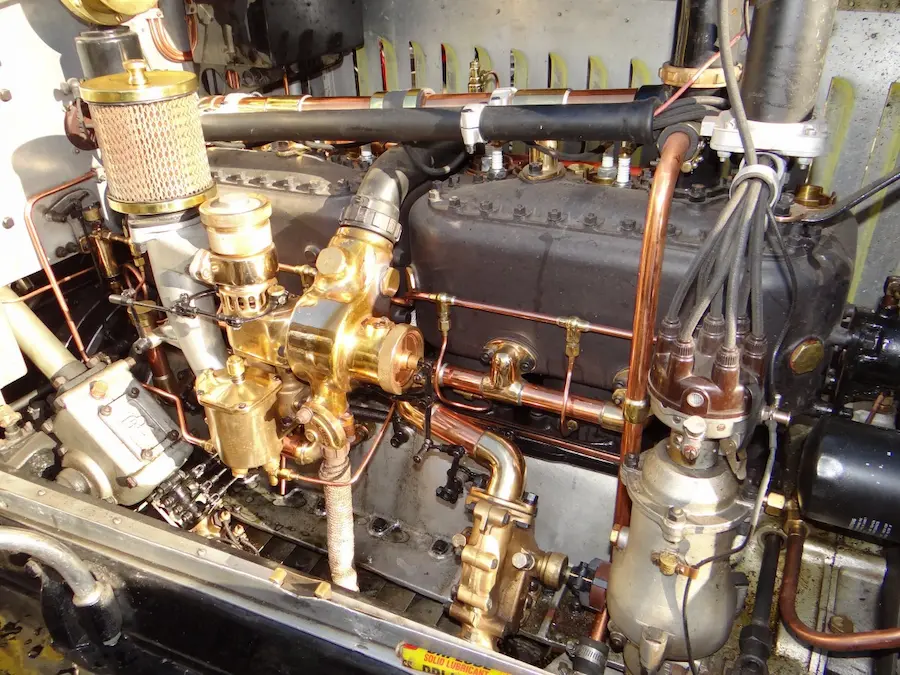

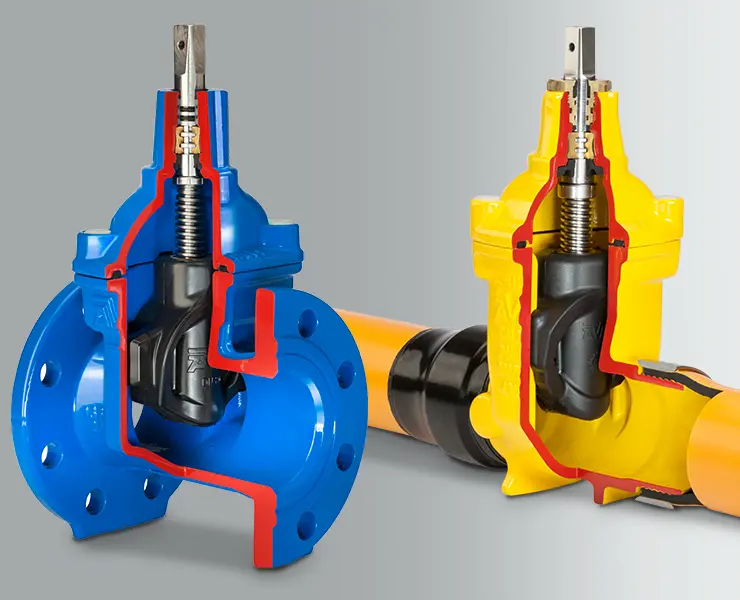

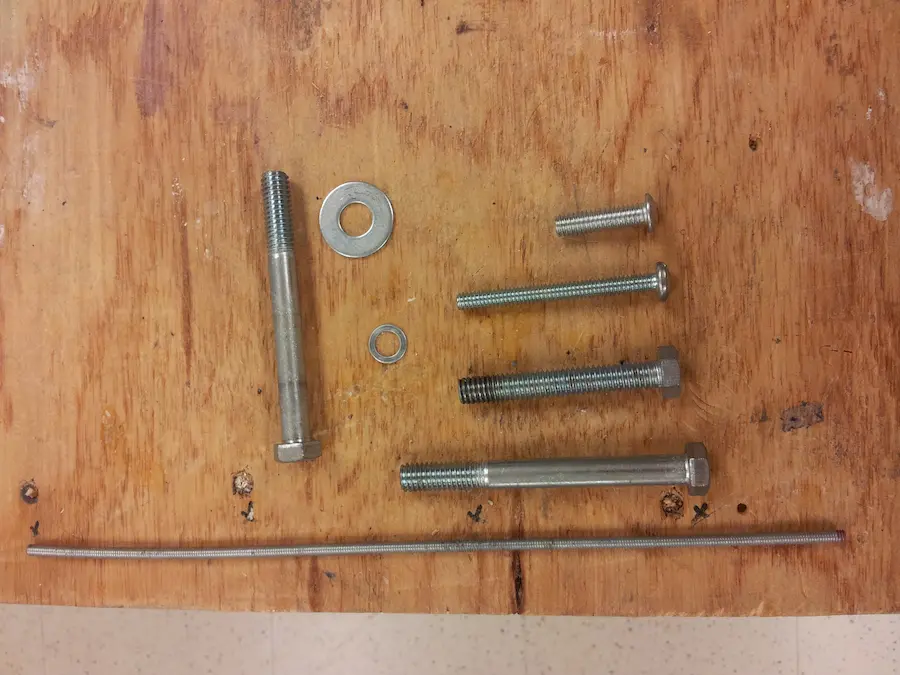

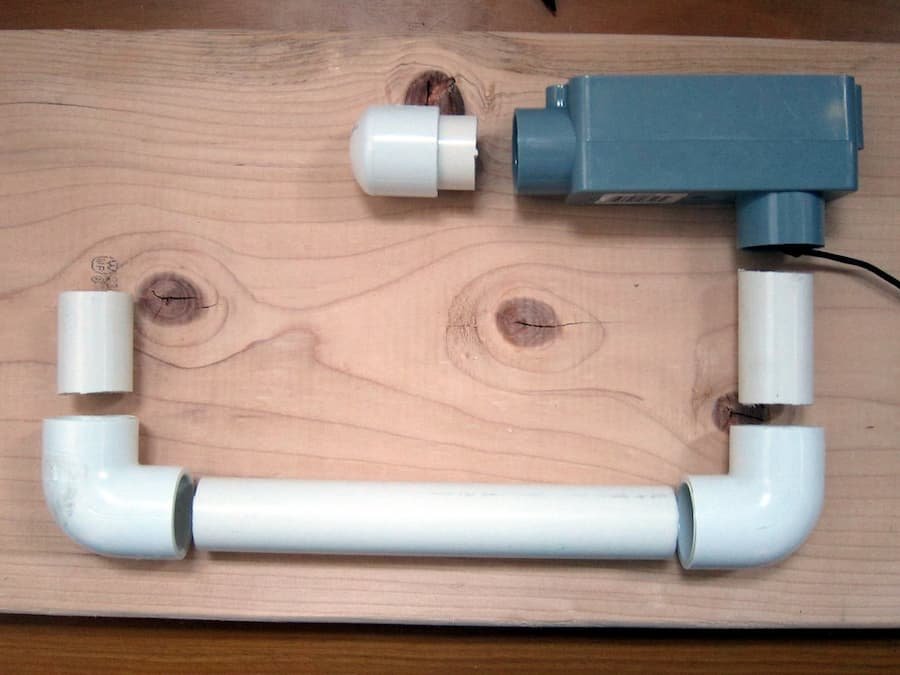

Pipeline Pigs

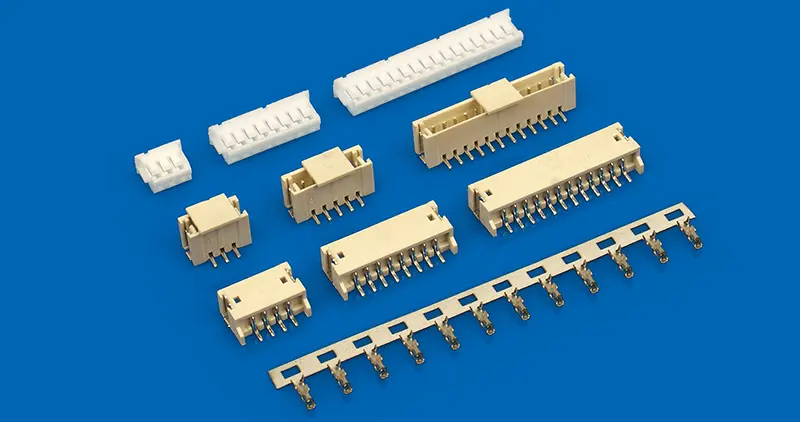

Pipeline pigs are essential maintenance tools known for their versatility and critical role in various maintenance functions. They are used for cleaning, separating products, and conducting inspections, ensuring comprehensive maintenance tailored to each project’s needs and improving pipeline integrity.

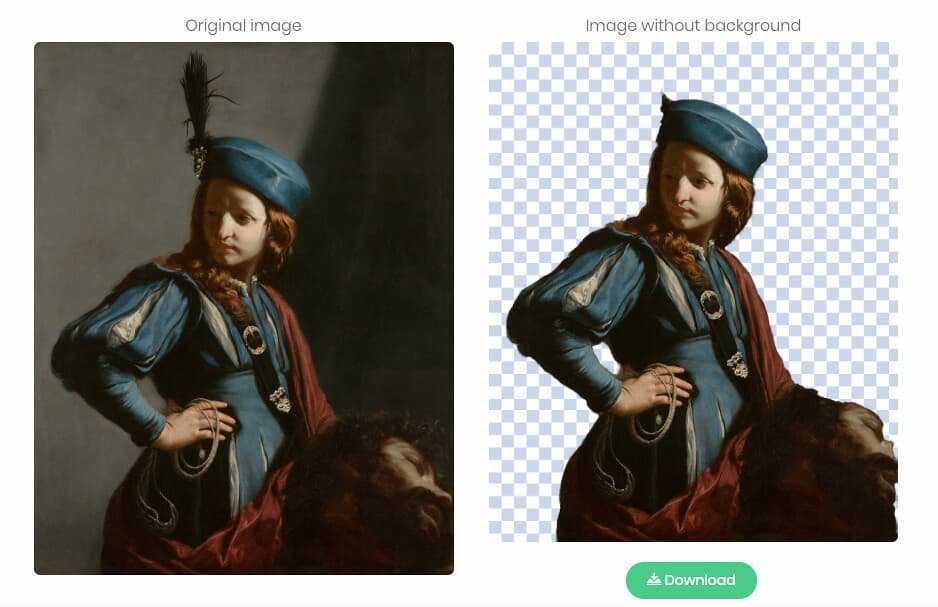

Inspection Cameras

Inspection cameras are a game-changer for viewing a pipeline’s internal conditions. They offer high-quality images and videos in real-time, aiding in spotting potential issues like corrosion, debris buildup and structural anomalies. This non-disruptive method allows for targeted maintenance, saving time and money.

Chemical Treatments

Chemical treatments are vital for maintaining pipelines transporting hazardous or viscous materials. They clean and protect internal surfaces, reducing risks like corrosion or buildup that can impede flow or cause damage. Regular treatment ensures peak operational conditions, minimizing unexpected disruptions and expensive repairs.

Techniques for Effective Maintenance

Routine Inspections

Regular pipeline inspections are essential for maintenance. They involve systematic assessments to detect wear and tear early. Scheduling these inspections helps operators catch issues before they become severe, saving money on repairs and reducing environmental risks to maintain pipeline integrity.

Pressure Testing

Pressure testing is crucial for pipeline readiness. It involves subjecting the pipeline to high pressures to find weaknesses. Regular tests ensure the pipeline can handle daily stress safely, preventing failures and ensuring operations run within safety margins.

Corrosion Control

Corrosion is a prominent challenge in pipeline maintenance that requires strategic intervention. Techniques for corrosion control include coatings and linings applied to the pipeline’s interior and exterior surfaces, alongside cathodic protection methods that prevent electrochemical reactions leading to corrosion. By implementing a thorough corrosion management strategy, pipeline operators may greatly increase the lifespan of their infrastructure and uphold safety and efficiency standards.

Innovations in Pipeline Maintenance

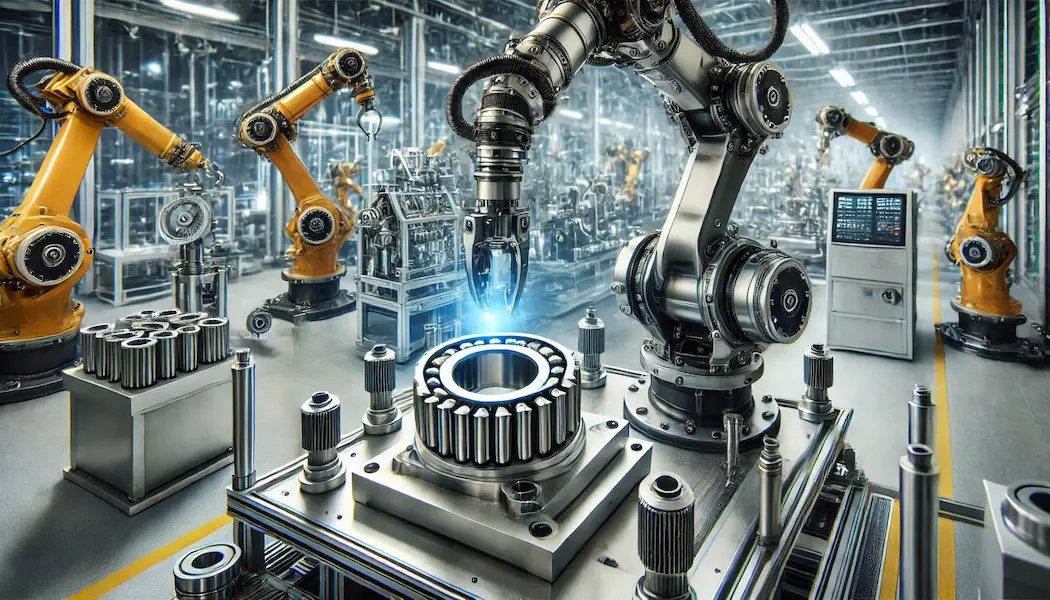

The realm of pipeline maintenance is no stranger to technological advancements, with the advent of drones and robotics heralding a new era of maintenance practices. Drones, equipped with advanced imaging technology, provide a safer and more efficient means of inspecting pipelines—especially in hard-to-reach or hazardous areas. Robotics, on the other hand, are being innovatively used for internal pipeline inspections and repairs. These advancements streamline maintenance efforts, reduce human risk, and enhance accuracy in diagnostics and repairs.

Moreover, intelligent pipeline technology, which employs sensors and automated systems, revolutionizes real-time monitoring. These systems enable operators to track pipeline performance continuously, offering immediate alerts to any anomalies that may indicate wear, leaks, or pressure issues. This proactive approach to maintenance ensures timely interventions, thus preventing potential disruptions and safeguarding the pipeline’s integrity over time.

Preventing Common Pipeline Problems

Common pipeline problems, such as stress corrosion cracking, pose significant risks to infrastructure health. Operators can reduce these problems by implementing specific methods after learning the root reasons. Preventive measures, such as selecting high-quality materials, adopting rigorous maintenance schedules, and employing corrosion-resistant coatings, minimize these risks. Through informed and proactive management, these measures help ensure the pipeline remains in optimal working condition, significantly reducing the likelihood of unforeseen breakdowns or failures.

Future of Pipeline Maintenance

Exciting advancements in sustainability and technology characterize the future of pipeline maintenance. Ongoing research and development efforts are focused on creating environmentally friendly maintenance solutions and exploring new materials that maximize efficiency and reduce environmental impact. Emerging technologies demand a fresh approach to pipeline care, promising a sustainable future for the industry through reduced carbon footprints and enhanced resource conservation.

In addition, current research into synthetic and composite materials is paving the way for constructing stronger, lighter, and more corrosion-resistant pipelines. These innovations are expected to redefine maintenance practices, minimizing routine upkeep demands while boosting overall pipeline performance. Integrating smart technologies with these next-generation materials will likely herald a transformative shift in how pipelines are designed, constructed, and maintained.

Final Thoughts

Pipeline maintenance remains a pivotal aspect of infrastructure management, ensuring safe and efficient operational continuity. By leveraging a blend of traditional methodologies and cutting-edge technologies, the industry can sustain high levels of operational excellence. As emerging technologies evolve, maintenance strategies will undoubtedly undergo further transformation, spotlighting the critical role of innovation and adaptability. Through the artful integration of these advancements, pipeline operators can optimally navigate maintenance complexities, fostering a future where efficiency and safety go hand in hand.

0