Key Takeaways:

- Understanding the critical role of water purity in manufacturing processes.

- Identifying industries where water purity significantly impacts product quality.

- Exploring solutions to common water impurity challenges.

- Learning real-world applications of water purity in various sectors.

- Examining technological advancements in water purification systems.

Table of Contents

The Importance of Water Purity in Manufacturing

Water is an indispensable component in a variety of manufacturing processes. Its quality is not merely a technical specification. Still, it is a critical determinant that can heavily influence the finished product’s reliability and safety. Industries such as pharmaceuticals and electronics are susceptible to water impurities due to the precision required during production. In the pharmaceutical industry, any contamination can result in significant health risks, making water purity essential for compliance with stringent regulations. In electronics, impurities can disrupt semiconductor manufacturing by introducing defects at the microscopic level, causing faults in the final product’s performance.

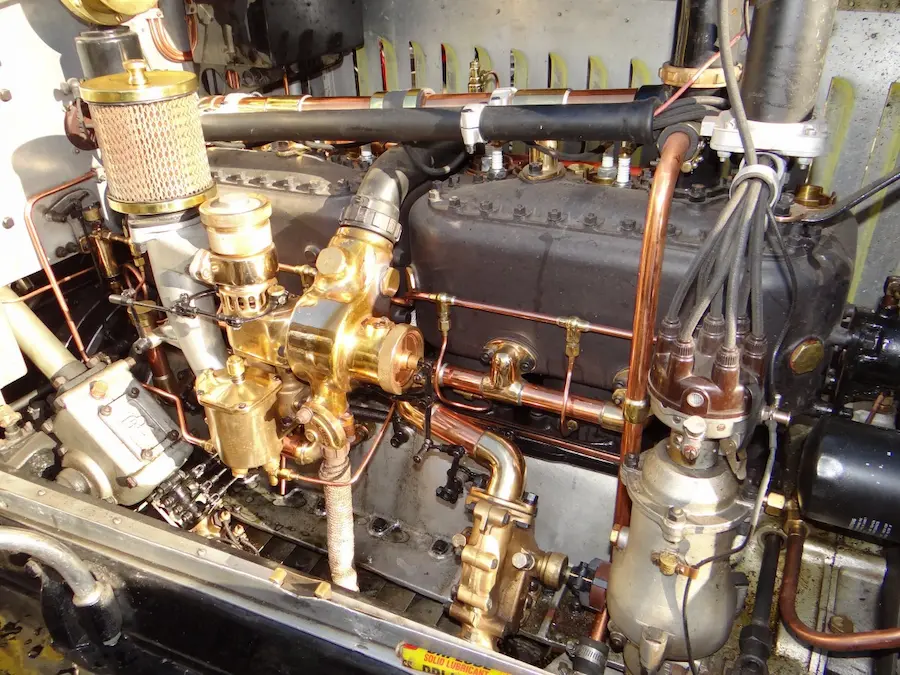

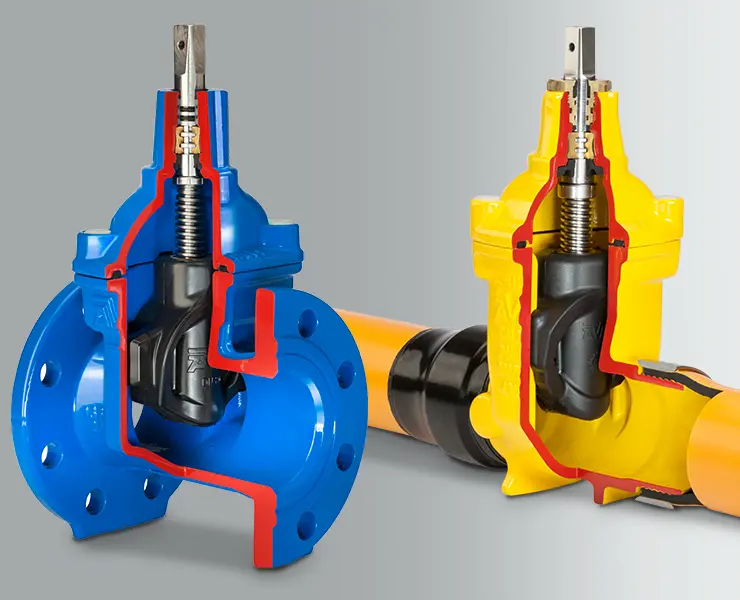

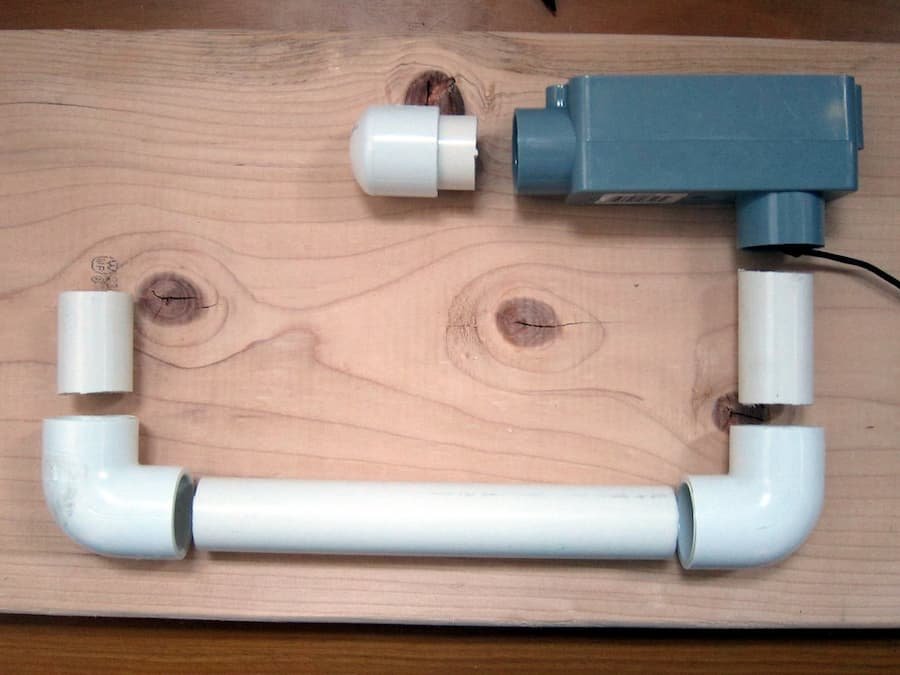

This focus on water quality has led to significant advancements in purification technologies. For instance, systems like the deionizer in Maryland can remove ionized salts and other charged molecules from water, delivering the high purity levels required for these critical applications. Such technologies are not just add-ons but prerequisites for achieving the precision and safety that today’s manufacturing demands. The implications extend beyond product quality and touch on environmental compliance, cost-effectiveness, and the sustainable growth of industries globally.

Industries Most Affected by Water Purity

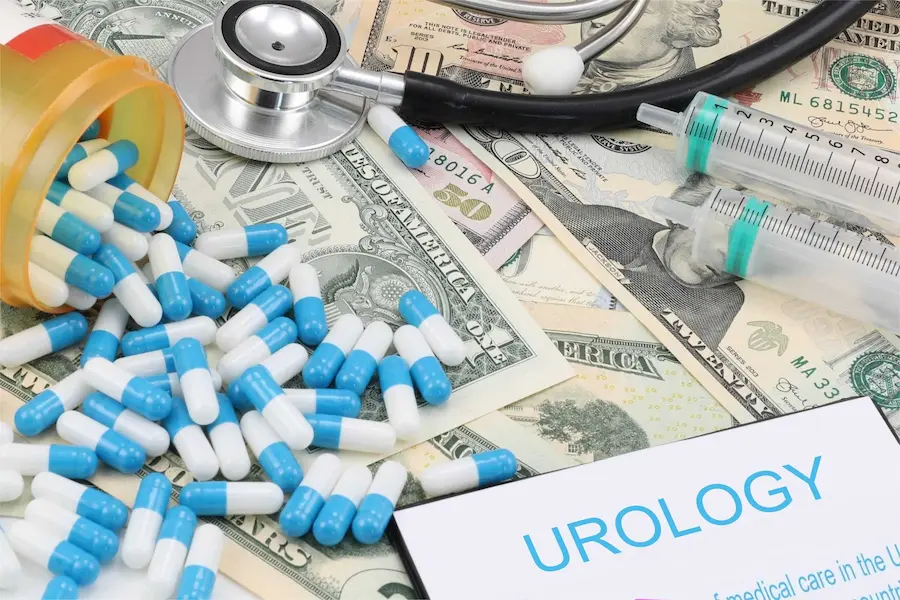

The impact of water purity spans numerous industries, each facing its unique challenges and standards. In the pharmaceutical sector, ultra-pure water is required not just for active pharmaceutical ingredient (API) production but throughout all stages of drug manufacturing. Contaminants, even in negligible amounts, can alter drug efficacy or stability, making water purification a non-negotiable part of the workflow. This adherence to stringent water quality standards is fundamental to ensuring that medications are safe and effective.

Similarly, water is a primary ingredient or a critical cleaning agent in the food and beverage industry. Its purity can influence consumer products’ flavor, appearance, and safety. Companies must often balance providing high-quality, safe products while minimizing costs and adhering to health regulations. Pure water is essential for product composition and consumer trust in the cosmetics industry. The purity of water here affects the texture and stability of products, their shelf life, and user safety.

Common Water Impurity Issues

Various impurities can be introduced into water during any manufacturing process, ranging from dissolved minerals and heavy metals to organic compounds and biological contaminants. These impurities present specific risks: they may disrupt chemical reactions, cause equipment corrosion, or introduce off-flavors or odors into products. Consequently, manufacturers must address these issues to sustain product quality and safety.

One of the significant consequences of ignoring water impurities is the formation of biofilms. These are colonies of microorganisms that can grow on surfaces, affecting operational efficiency and hygiene. If left unchecked, biofilms can harbor pathogens, posing serious health risks in industries like food processing and pharmaceuticals. They can also clog pipes and damage equipment, leading to costly repairs and downtime.

Real-World Applications of Water Purity

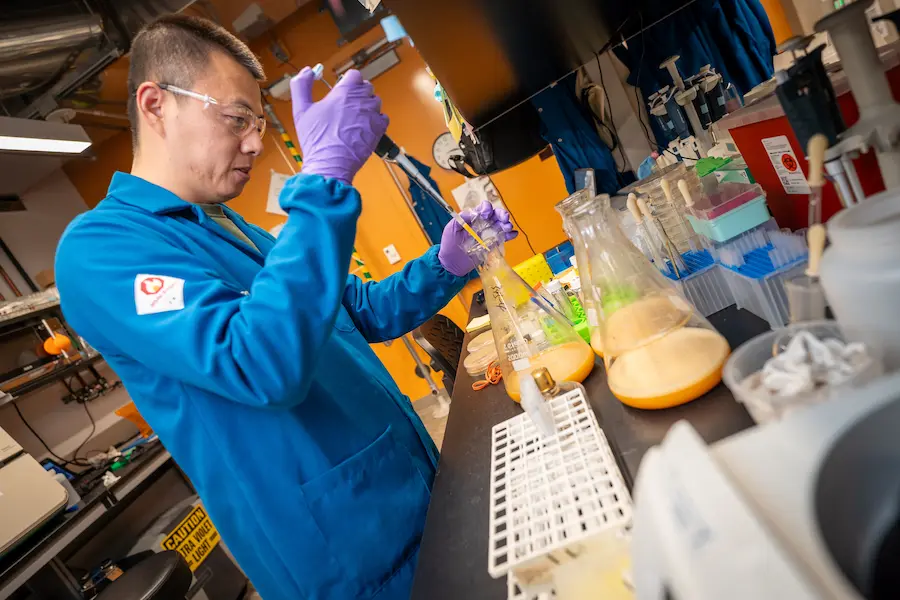

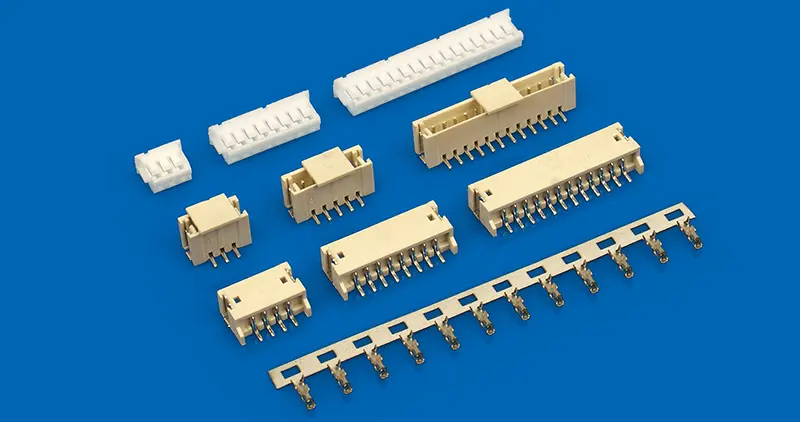

The critical importance of water purity can be observed in various industrial uses. In electronics manufacturing, particularly semiconductors, super-pure water is utilized to wash silicon wafers during production. Even the slightest impurities can significantly affect semiconductor devices’ electrical properties and yield, making high water purity non-negotiable in achieving the desired product outcomes.

In cosmetics, pure water ensures that products like lotions and creams remain stable over time and safe for consumer use. Any impurities in the water used during formulation can lead to spoilage or adverse skin reactions, damaging a brand’s reputation and leading to financial losses.

Technological Advancements in Water Purification

Advancements in water purification technology have revolutionized how industries handle water treatment. Systems such as reverse osmosis and nano-filtration have set new benchmarks for water purity by effectively removing dissolved solids, bacteria, and other contaminants that traditional filtration could leave behind. Additionally, ultraviolet (UV) purification methods add another layer of protection by inactivating microbes, providing a chemical-free method to achieve high water quality.

These technological improvements enhance water quality and align with contemporary sustainability objectives by reducing water waste and lowering energy consumption. Such innovations are crucial in supporting industries’ adaptation to stricter environmental regulations while contributing positively to resource conservation efforts. The World Health Organization emphasizes the ongoing global pursuit of better water quality, underscoring the critical need for technological advances in public health and industrial settings.

Solutions for Manufacturers Facing Water Purity Challenges

To mitigate the challenges associated with water impurities, manufacturers can adopt a strategic approach that includes regular monitoring, innovative technology, and workforce training. Implementing comprehensive water testing protocols ensures early detection of contaminants, allowing manufacturers to act swiftly to rectify any issues. Investing in and maintaining state-of-the-art purification systems is also vital.

Moreover, training employees about water management best practices can empower them to identify potential problems and implement solutions proactively. Collaborating with water treatment experts can provide manufacturers with tailored solutions that address specific water quality challenges. Real-time monitoring technologies can offer valuable insights and drive operational efficiencies by ensuring consistent water standards are met.

0