Table of Contents

Introduction to Metal Casting Careers

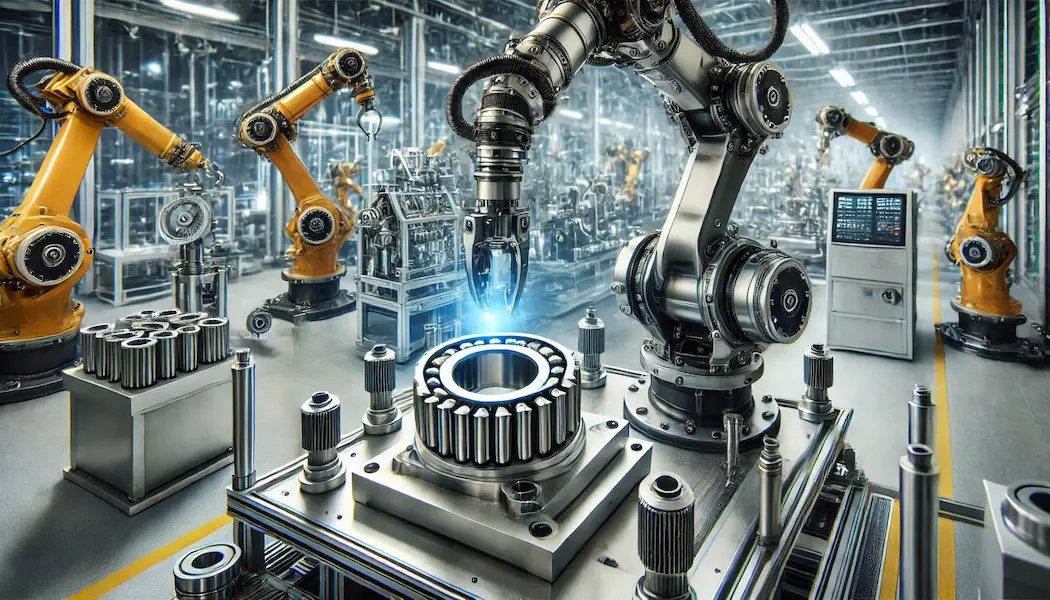

Metal casting is a foundational industry with diverse career paths. Understanding where to start can be overwhelming for newcomers. Whether you aim to explore manufacturing career opportunities in Pryor, OK, or any other location, this article aims to demystify the industry and provide a roadmap for those considering a career in metal casting.

As manufacturing continues to evolve and grow, it’s important to recognize the vast opportunities within the metal casting sector. This industry plays a crucial role in producing essential components for various sectors, from automotive to aerospace. For many, a career in metal casting provides job stability and the opportunity to contribute to vital national industries.

Essential Skills for Success

Successful metal casting professionals possess a mix of technical and soft skills. Key skills include an understanding of metallurgy, precision, problem-solving, and teamwork. According to experts, continuous learning is crucial for staying updated with industry advancements.

Creative thinking can set you apart in this field. For instance, developing a new method to reduce casting defects can significantly improve the production process. Moreover, strong communication skills are necessary to effectively relay information across different teams within the plant. Additionally, being adept in data analysis can aid in optimizing manufacturing processes, thereby boosting efficiency and reducing wastage.

Types of Jobs in Metal Casting

The metal casting industry offers a range of jobs, from entry-level positions to specialized roles. Common job titles include foundry worker, metallurgist, quality control inspector, and production manager. Each role has specific responsibilities and skill requirements.

Entry-Level Positions

Foundry workers and machine operators often start their careers with minimal prior experience. These roles involve handling molten metals and operating casting machinery. Typically, these positions focus on basic operations and require rigorous adherence to safety protocols to prevent accidents.

Specialized Roles

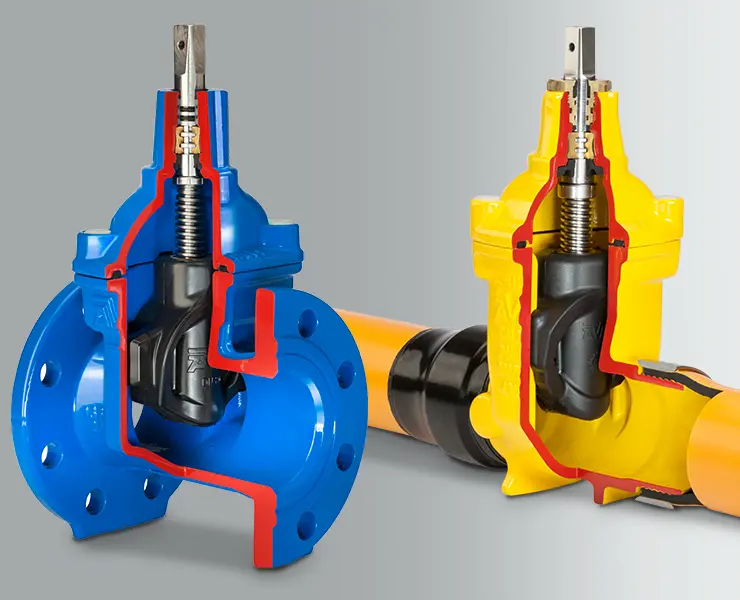

Metallurgists and quality control inspectors require more advanced knowledge and education. These professionals focus on metal properties and ensure that cast products meet quality standards. Metallurgists often develop new alloys and improve existing ones, while quality control inspectors use various techniques and tools to test the integrity and durability of metal products.

Education and Training Pathways

While some entry-level positions require only a high school or a hr diploma, advancing in the field often necessitates specialized training or a degree in materials science or engineering. Trade schools and technical colleges offer programs that cater to this industry. For more information on education pathways, refer to CareerOneStop.

Gaining hands-on experience through internships and apprenticeships can also be invaluable. These programs provide real-world experience that can make candidates more attractive to employers. Furthermore, certification programs offered by institutions like the American Foundry Society can bolster credentials and open doors to higher-level positions.

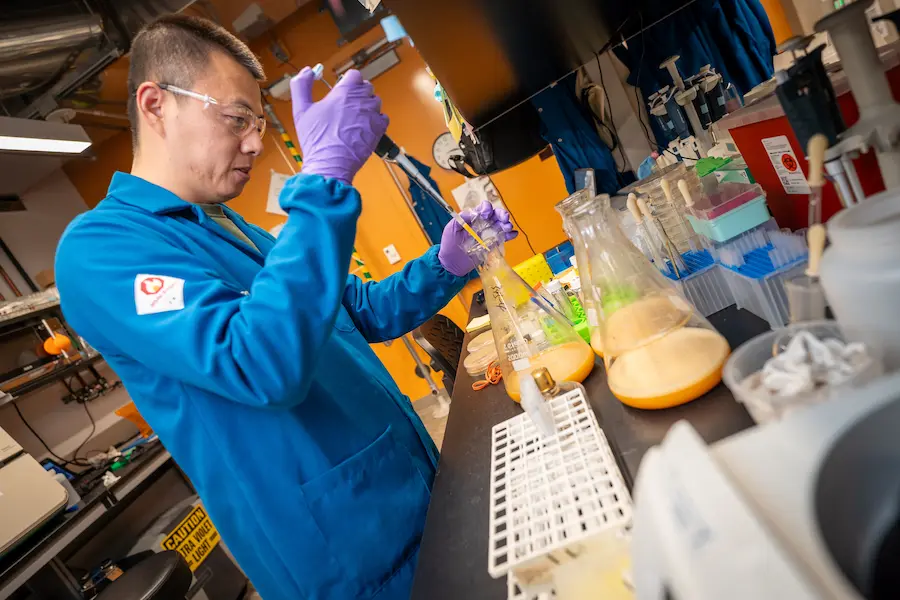

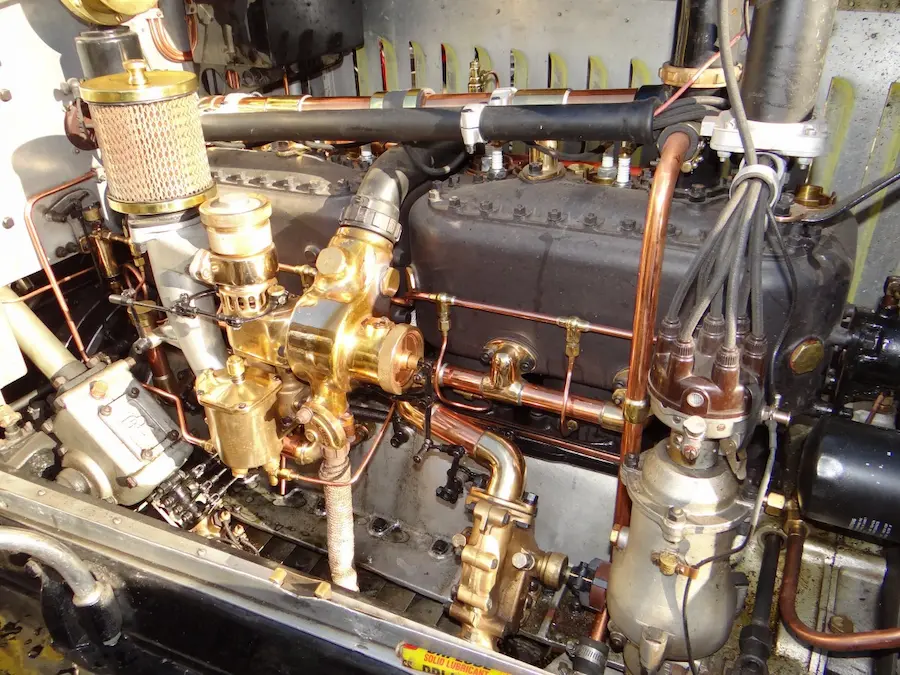

Work Environment and Safety

The work environment in metal casting can be rigorous, involving heavy machinery, high temperatures, and potential hazards. Employers place a strong emphasis on safety protocols to protect workers. To learn more about workplace safety standards, visit the OSHA website.

Compliance with safety regulations is non-negotiable in this industry. It takes frequent training sessions and up-to-date safety equipment, such face shields, heat-resistant gloves, and fire-retardant clothes, to reduce dangers and guarantee a secure workplace. Companies also invest in advanced ventilation systems to mitigate the harmful effects of exposure to fumes and molten metals.

Advancement Opportunities

Career advancement in metal casting can be achieved through experience, additional education, and acquiring certifications. Roles such as plant manager or production supervisor often require years of hands-on experience and a solid understanding of the production process.

Continuous professional development is key. Taking leadership or project management courses can help prepare you for higher-level positions and responsibilities. Attending pertinent conferences and networking within industry associations can provide offer perspectives and chances for professional development.

Challenges in the Industry

Like any sector, metal casting has its share of difficulties, such as a lack of qualified workers and environmental issues. In order to overcome these obstacles, creative thinking and an openness to change are needed. Investing in cutting-edge techniques and sustainable technologies can assist in reducing some of these difficulties. For example, adopting eco-friendly materials and processes can reduce the environmental impact of metal casting operations. Furthermore, companies can establish partnerships with educational institutions to create training programs that address the skills gap, ensuring a steady pipeline of qualified professionals.

Future Trends in Metal Casting

Technological advancements are shaping the future of metal casting. Automation, 3D printing, and sustainable practices are becoming integral to modern foundries. Keeping abreast of these trends can position professionals to capitalize on emerging opportunities.

As the industry evolves, the demand for skilled professionals who can operate and maintain advanced machinery will likely increase. It will be essential for people wishing to progress in their metal casting jobs to stay current with emerging technologies. Artificial intelligence (AI) and the Internet of Things (IoT) are two emerging concepts that have the potential to completely transform the industry by decreasing human error and increasing the efficiency of industrial processes.

0