When we think of stainless steel, our minds often wander to kitchen appliances, surgical instruments or shiny railings. But did you know that behind all of these sleek yet durable products lies a skilled profession called stainless steel fabrication? Fabricators transform raw stainless steel into functional structures with striking aesthetic appeal – we will explore this craftful discipline here on this blog. Stainless steel fabricator like MartinStainlessSteel transforms raw metal into functional, eye-catching structures. In this blog series, we will dive into this remarkable field by exploring its scope, significance and artistic flair that make up this remarkable craft.

Table of Contents

How to Craft the Art of Stainless Steel Fabrication

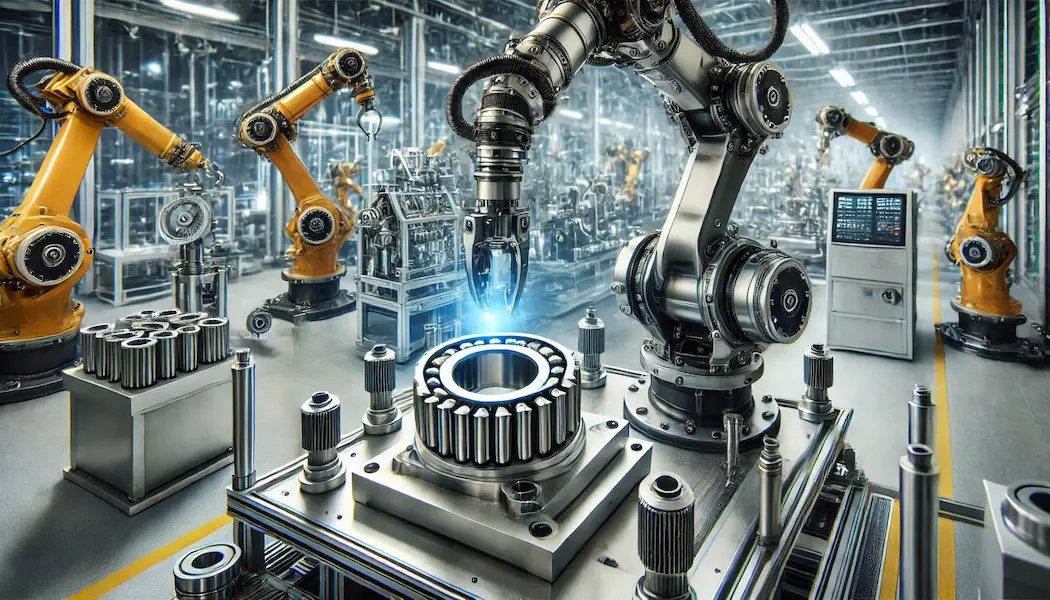

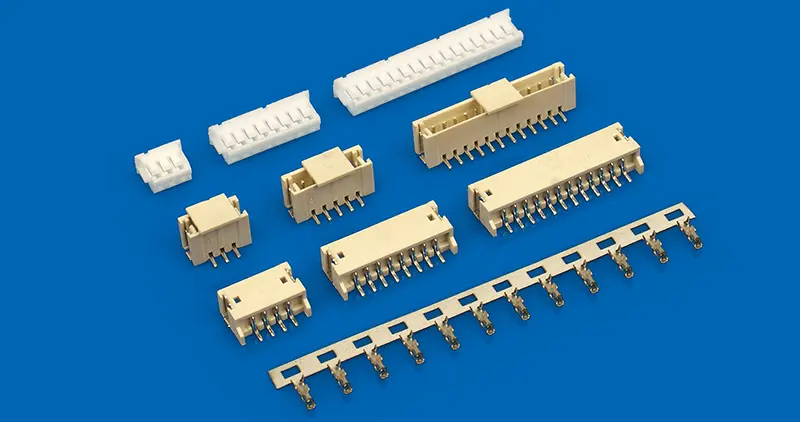

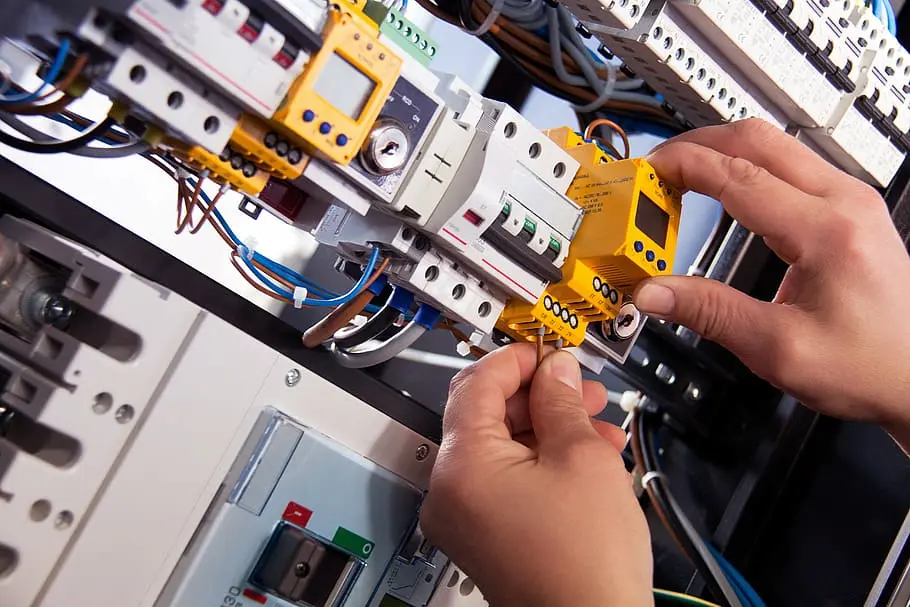

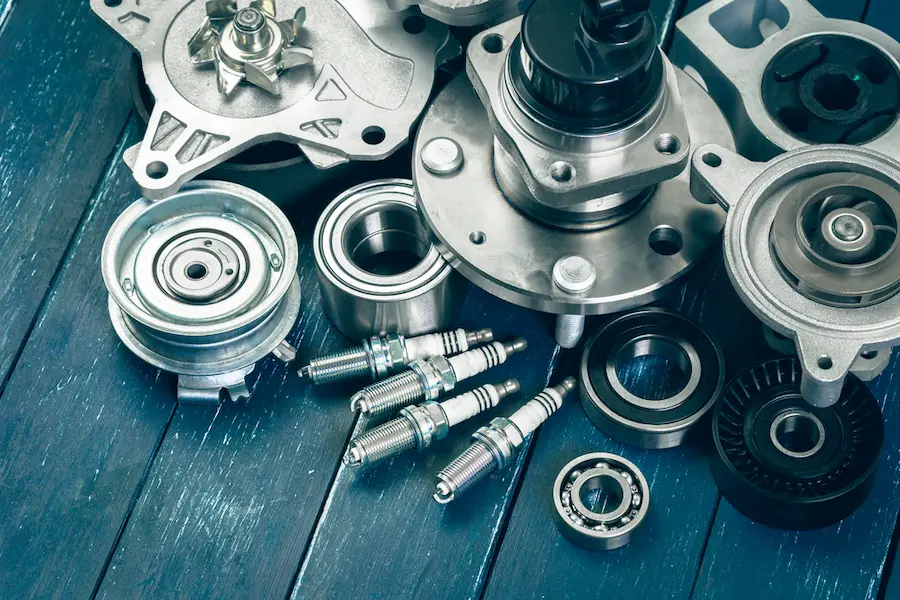

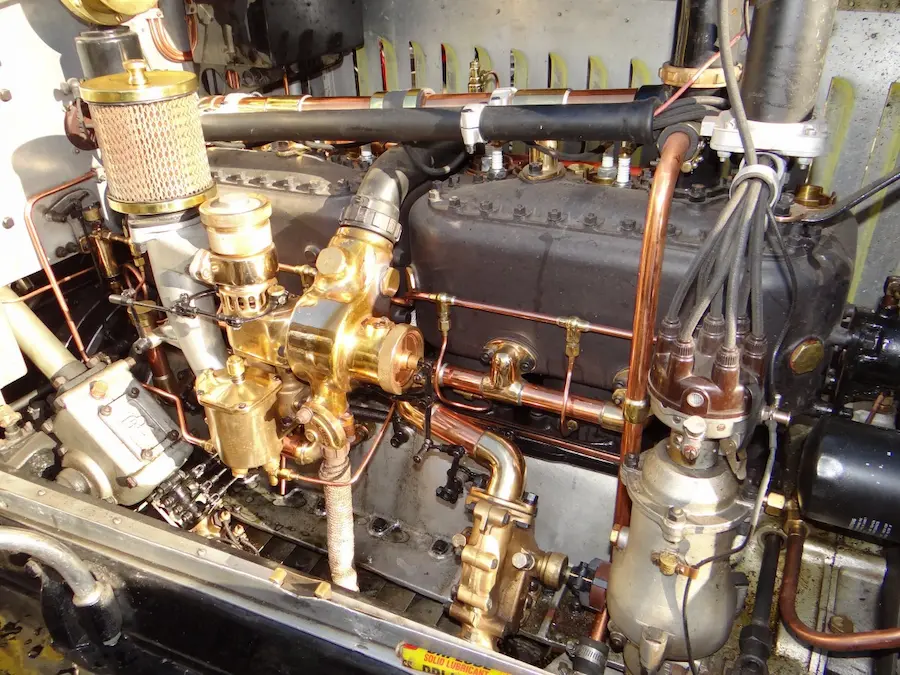

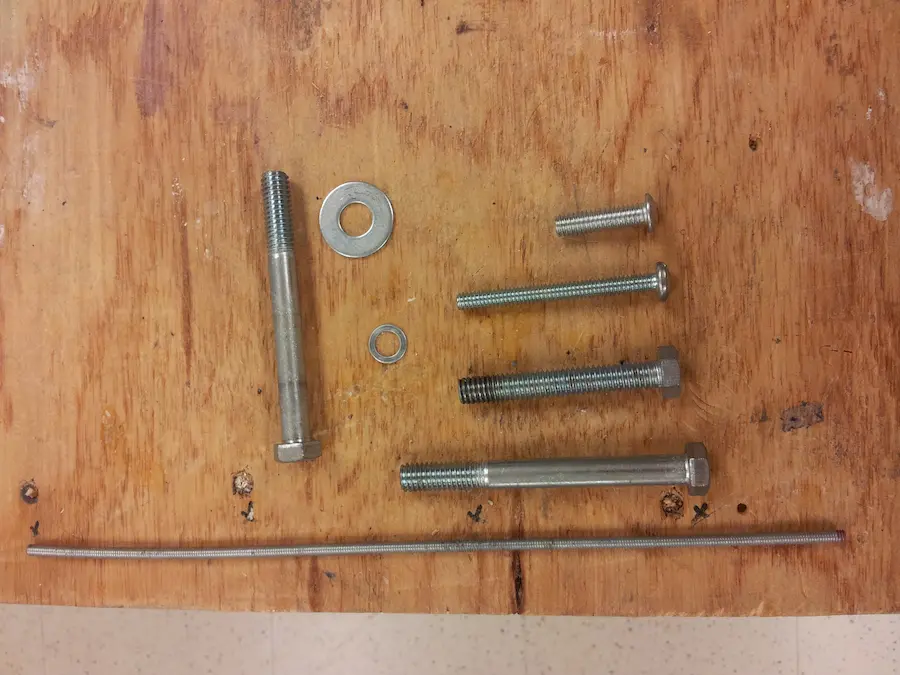

Stainless steel fabrication is a highly skilled art that involves shaping, cutting, welding and assembling stainless steel into structures or products with various structures or products. Fabricators work with an exceptional material known for its corrosion resistance, strength and lustrous appearance.

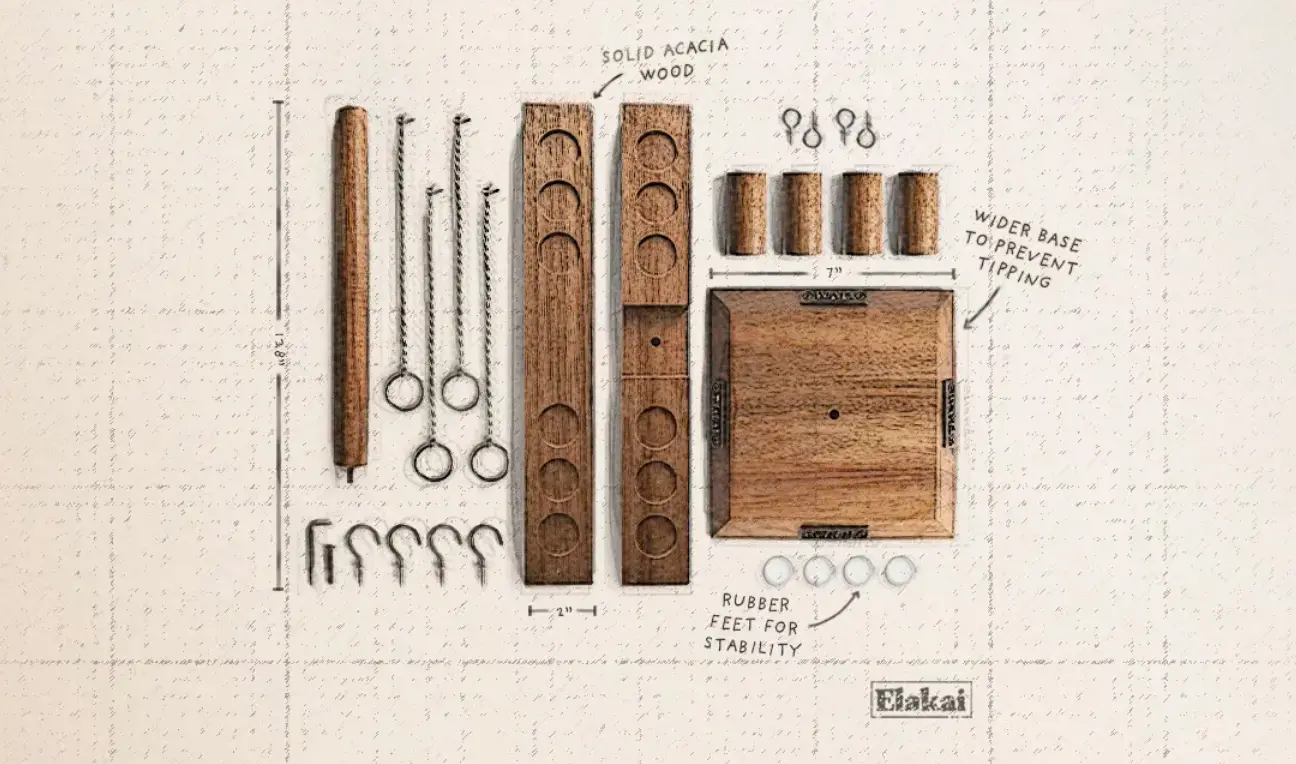

Design and Planning: Every project begins with design. Stainless steel fabricators collaborate closely with engineers, architects, and clients to conceptualize the end product – this involves taking precise measurements, selecting materials for selection, and creating structural plans for every stage of fabrication.

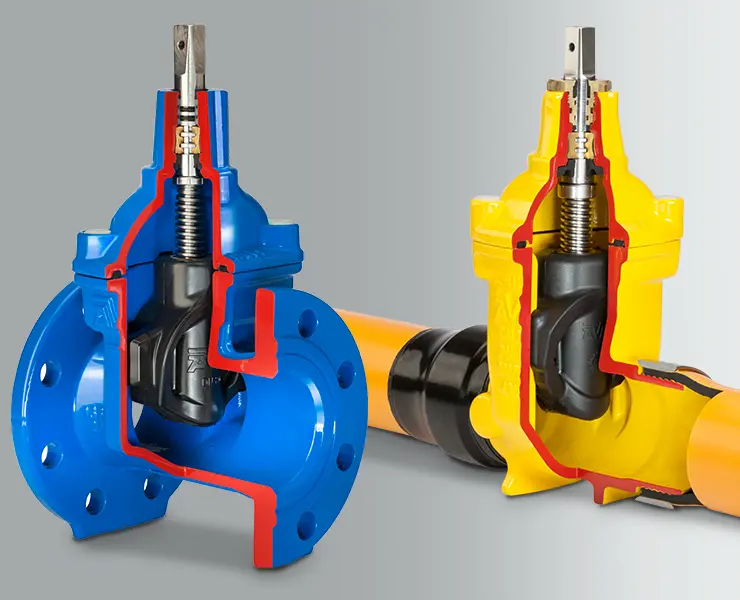

Cutting and Shaping: Once the design has been finalized, cutting the stainless steel sheets or tubes to meet specific dimensions is next. Precision here is of utmost importance as any deviation could compromise the integrity of the final product.

Welding and Joining: Fabricators of stainless steel use welding techniques to assemble cut pieces together into an undivided structure, an important step that determines its strength and lifespan. This step plays an integral part in fabricating high quality stainless steel products.

Finishing Touches: Once the primary structure is in place, fabricators add finishing touches such as polishing, sanding and coating to enhance both its appearance and corrosion resistance. These steps not only increase aesthetic value but also strengthen material integrity against future corrosion attacks.

Quality Control: Stringent quality controls must be in place to ensure that fabricated products adhere to all specifications and safety regulations.

Why Stainless Steel Fabrication Is Crucial

Fabricating stainless steel is a crucial field, serving many vital purposes:

Durability: Stainless steel’s resistance to rust and corrosion make it an excellent material choice. Fabricated products made of stainless steel last for many years without needing replacement parts or incurring maintenance costs, thereby lowering maintenance costs and environmental impacts.

Aesthetic Appeal: Stainless steel’s glossy surface adds elegance and modernity to structures, making it an attractive choice in architecture and interior designs.

Hygiene and Safety: For medical and food industries, stainless steel is a top choice due to its ease of cleaning and nonreactive nature – both features that help ensure the highest standards of hygiene and safety.

Structural Integrity: Stainless steel’s strength and ductility makes it ideal for creating sturdy yet reliable structures such as bridges or industrial equipment.

Artistic Aspect of Stainless Steel Fabrication

Stainless steel fabrication is more than simply the assembly of components; it’s an art form requiring precise craftsmanship, creativity, and an attention to detail.

Fabricators Must Employ Precision: Fabricators must cut stainless steel with exactitude, to ensure seamless integration of its components. Even an inch or millimeter of difference could prove pivotal.

Master Welding Techniques: Welding is like sculpture; fabricators must bring pieces together with seamless joints using various welding techniques and have an eye for detail to achieve the best result. To succeed at welding requires mastery over various welding methods and an eye for detail.

Customization and Creativity: Stainless steel fabrication offers unparalleled creative freedom to meet individual needs and aesthetic requirements. This allows for infinite customization that caters specifically to aesthetic preferences and individual aesthetic requirements.

Balance between Form and Function: For stainless steel fabricators to achieve excellence in their craft, they must find the delicate balance between functional needs of their products and aesthetic appeal. This fusion between form and function encapsulates true artistry.

Stainless Steel Fabrication Has Many Advantages

Stainless steel fabrication’s applications are endless, from architectural marvels to daily essentials; its impact can be felt everywhere around us.

Architectural Marvels: Stainless steel has become a standard in contemporary architecture, appearing on skyscrapers, bridges and public art installations alike.

Kitchen Elegance: Our homes feature stainless steel in the form of appliances, countertops and sink units that exude elegance.

Industrial Machinery: Due to its durability and resistance against harsh environments, stainless steel machinery is used extensively in manufacturing environments.

Medical Marvels: Stainless steel has become an invaluable material in medical instruments, devices and hospital equipment where precision, cleanliness and long-term reliability are imperative.

Conclusion:

Stainless steel fabrication is an amazing blend of science and art. As a craft that marries strength with functionality, fabrication marries both. From architectural achievements to everyday items that grace our homes, stainless steel fabrication enriches our lives in ways we may not always notice. Next time you admire a polished stainless steel railing or use one of your stainless steel kitchen appliances, remember the skilled hands who transformed raw steel into functional art.

0