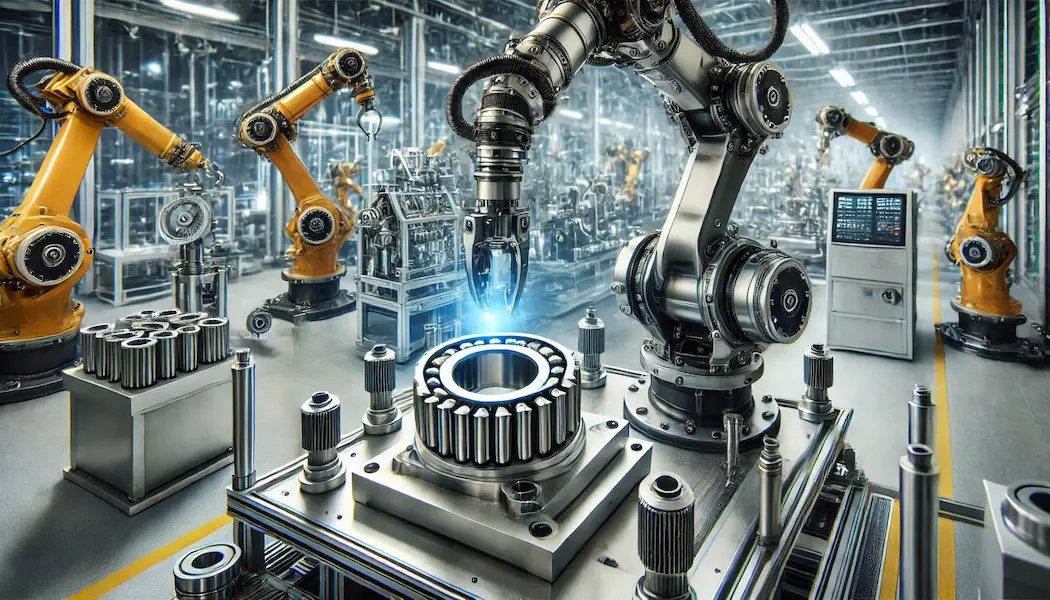

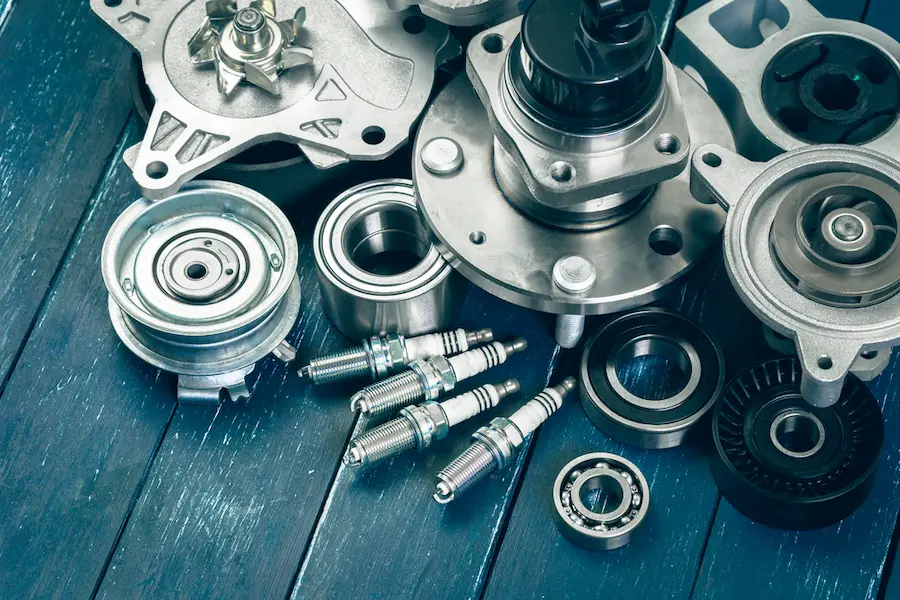

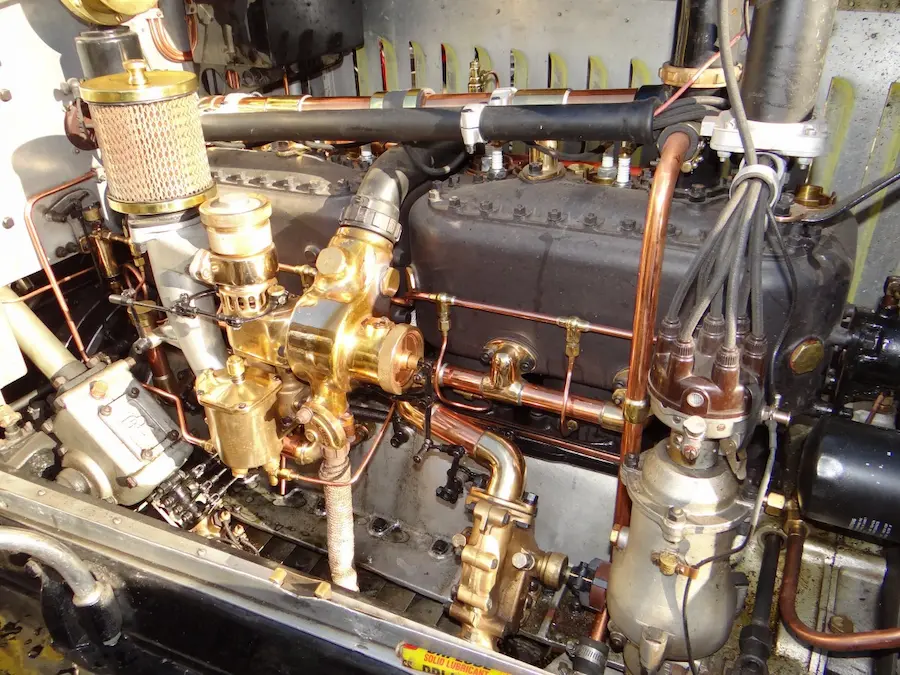

In industries where machinery is a vital component of operations, ensuring optimal performance and minimizing downtime are top priorities. One effective way to achieve this is through the use of handheld vibration analyzers. These devices play a crucial role in predictive maintenance programs by detecting and diagnosing potential equipment issues before they escalate into costly failures.

Table of Contents

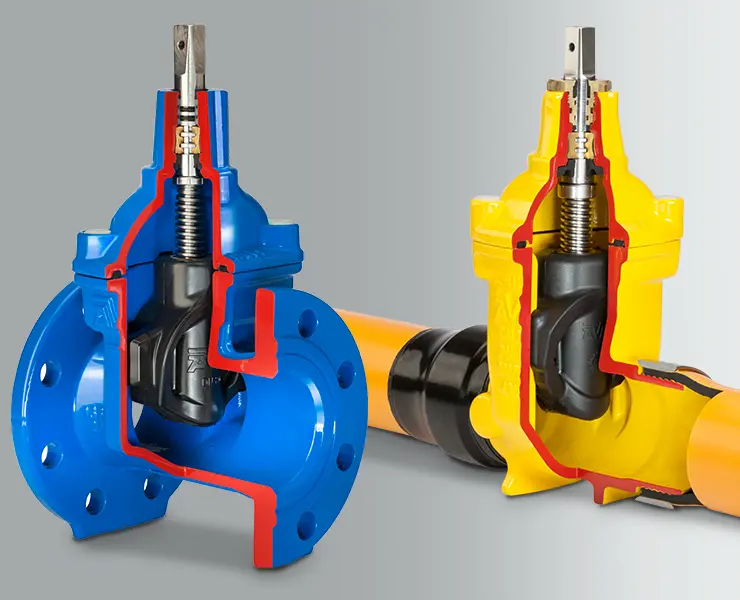

Understanding the Importance of Vibration Analysis

Vibration analysis is a predictive maintenance technique that involves monitoring the vibration levels of machinery to identify abnormal patterns or signs of wear and tear. By analyzing vibration data, maintenance professionals can pinpoint underlying mechanical issues such as misalignment, imbalance, bearing faults, and structural defects. Early detection allows for timely intervention, preventing unexpected breakdowns and prolonging equipment lifespan.

Key Features to Consider

When selecting a handheld vibration analyzer for your maintenance team, several factors should be taken into account to ensure you choose the most suitable device for your needs:

1. Accuracy and Sensitivity

Look for a vibration analyzer that offers high accuracy and sensitivity in detecting vibration signals across a broad frequency range. This ensures reliable data collection and precise diagnosis of machinery condition.

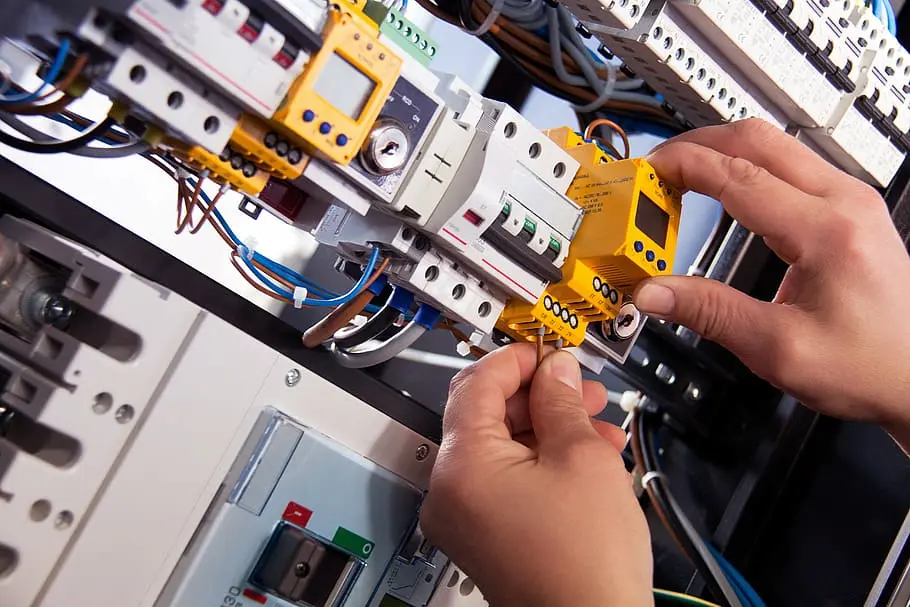

2. Portability and Durability

A portable vibration analyzer is essential for maintenance teams working in diverse environments, including industrial facilities, manufacturing plants, and field locations. Opt for a rugged and durable device that can withstand harsh conditions and frequent use.

3. Data Collection and Analysis Capabilities

Choose a vibration analyzer equipped with advanced data collection and analysis features. The ability to store, analyze, and trend vibration data enables maintenance professionals to track equipment health over time and make informed maintenance decisions.

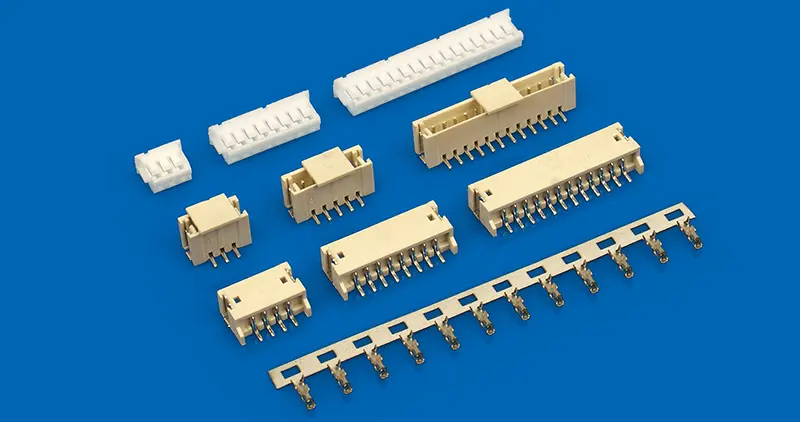

4. Compatibility and Integration

Ensure that the vibration analyzer is compatible with a wide range of machinery and equipment types. Look for devices that offer seamless integration with existing maintenance management systems and software platforms for streamlined data sharing and analysis.

5. User-Friendly Interface

An intuitive user interface is essential for simplifying the vibration analysis process and minimizing training requirements for maintenance personnel. Look for features such as touchscreen displays, customizable settings, and intuitive navigation menus.

The Benefits of Using Handheld Vibration Analyzers

Investing in handheld vibration analyzers offers several benefits for maintenance teams and organizations:

1. Early Detection of Machinery Issues

By regularly monitoring vibration levels, maintenance professionals can detect potential equipment problems at an early stage, allowing for proactive maintenance interventions and minimizing unplanned downtime.

2. Improved Equipment Reliability and Performance

Timely maintenance based on vibration analysis data helps optimize equipment performance and reliability, resulting in increased productivity and operational efficiency.

3. Cost Savings

Preventive maintenance strategies enabled by handheld vibration analyzers help reduce repair costs, extend equipment lifespan, and avoid production losses associated with unexpected breakdowns.

4. Enhanced Safety

Identifying and addressing machinery issues promptly contributes to a safer work environment by reducing the risk of equipment-related accidents and injuries.

Choosing the Right Handheld Vibration Analyzer

When selecting a handheld vibration analyzer for your maintenance team, it’s essential to consider your specific requirements, budget constraints, and long-term maintenance goals. Conduct thorough research, read product reviews, and consult with industry experts to make an informed decision.

For maintenance professionals seeking a reliable and versatile portable vibration analyzer, portable vibration analyzer offered by leading providers can meet the demands of diverse industrial applications. These advanced devices combine precision, portability, and user-friendly features to streamline vibration analysis processes and optimize maintenance workflows.

Conclusion

Handheld vibration analyzers play a vital role in predictive maintenance programs, enabling maintenance teams to identify and address potential equipment issues before they result in costly downtime and disruptions. By investing in the right vibration analysis tools and adopting proactive maintenance strategies, organizations can optimize equipment performance, enhance reliability, and achieve significant cost savings in the long run.

0